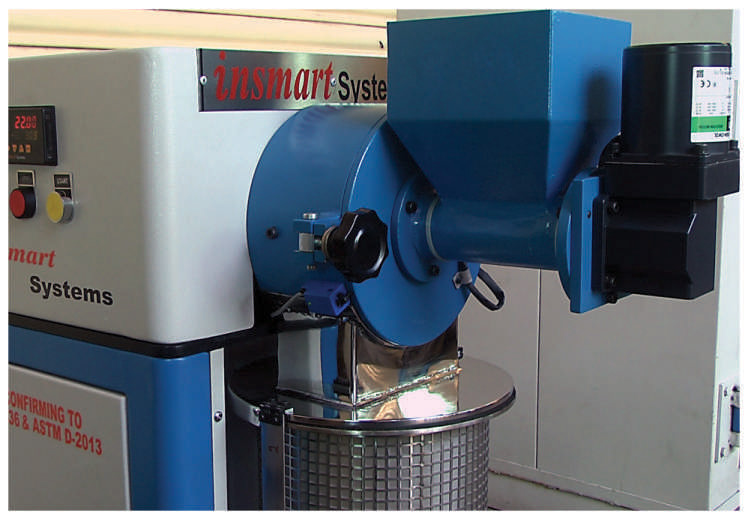

Hammer Mill – most ideal for Coal / Coke Pulverizing

Ideal for milling even easily oxidizable coal samples with upto ~12% superficial moisture without external air drying.

No flying dust escapes the mill and thus all the fed material is contained within the mill and collected for analysis.

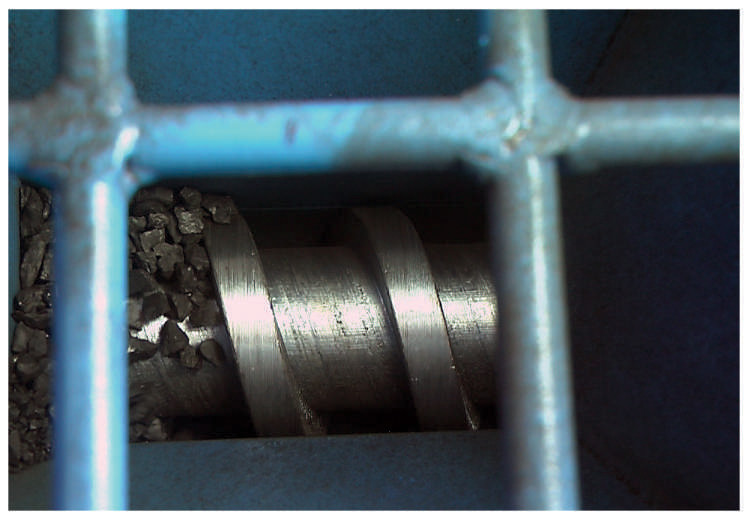

A highly innovative helical feeding system ensures regulated feeding in the grinding zone.

A safety hopper mesh to protect operators hand from entering the grinding zone during material feeding.

A Positive air flow system to transfer the ground material into collection bin eliminates manual cleaning of the grinding zone after each operation.

No need of additional dust extraction system

Pulverizes small quantity of Laboratory sample (upto 5 Kg/hour). Sample upto a maximum size of -5 mm can be pulverized to – 212 micron as per the defined particle size distribution in IS 436.

The coal sample to be ground is introduced into the pulverizing chamber through a hopper. The material travels through a helical screw and it is uniformly delivered into the grinding chamber.

The rapidly rotating hammer’s centrifugal force disintegrates material by shearing action between the fixed toothed circular inserts and rotating hammer arms.

As particles get smaller than the size of underneath sieves, the material passes through the sieve mesh and gets collected in a stainless steel container.

No dust is dissipated in the process. Need for separate dust extraction is eliminated and no sample is lost.

Small space separating the toothed circular inserts and rotating hammer arm plates determine the product fineness.

| Equipment | Air Dried Sample | Sample without air drying | Sample with cross seam material / high density material |

| Insmart Hammer Mill | Air drying of sample (upto 400C) before pulverization is permissible as per IS 16143 | Accepts samples with upto 12% surface moisture content | Accepts samples with material density upto 2 T/m3 |

| Other Make Hammer Mill | Mostly accept material after air drying | Feature not available | Leads to sieve puncturing in most cases |

<63 Micron upto 20-25%

+63 Microns to -125 microns upto 40-45%

+125 Microns to -212 Microns upto 30-35%

| Working principle | Impact action |

| Max. feed size | Upto 5 mm |

| Output size | Upto 212 microns |

| Capacity | 5000 gms / hour |

| Grinding Material | Coal, Coke |

| Toothed circular inserts | Size: 200mm |

| Grinding Media with Rotating Hammer Arms &

Hammer mill Sieves |

Hardened Steel / Tungsten Carbide Lined / Stainless Steel |

| Sieves

|

Interchangeable sieves of following sizes can be provided -850 microns, -250 microns, -212 microns |

| Motor Drive | 1.5 Kw, 2 HP , RPM: 2800, 415V, 3 phase induction motor. |

| Dimension | L= 680mm, W= 530 mm, H= 1070mm |

| Weight of machine | 150 Kgs |