Toothed Roll Crusher

Insmart Toothed Roll Crusher

The machine is designed to crush collected gross sample of “Run of Mines Coal” or “Coal large”, which generally contains Upto 150mm size coal with a few lumps of -230mm. The machine crushes the gross sample Upto -50mm size with less generation of fines.

The crushed material comes out from the crushing zone and gets discharged into a large collecting receptacle. An operator loads the gross-sample in batches of 25kg into the vibratory feeder hopper manually.

The vibratory feeder conveys the coal into the crushing zone. Two toothed rollers rotating at high speed crush the large coal lumps upto – 50mm size. The crushed – 50mm coal sample falls directly on a bin.

- Roll crushers are used in open-pit mining (ROM) for primary, secondary and tertiary crushing. Processes like this require tough and durable machinery, and we provide advanced stationary roll crushers that can handle a range of seam materials.

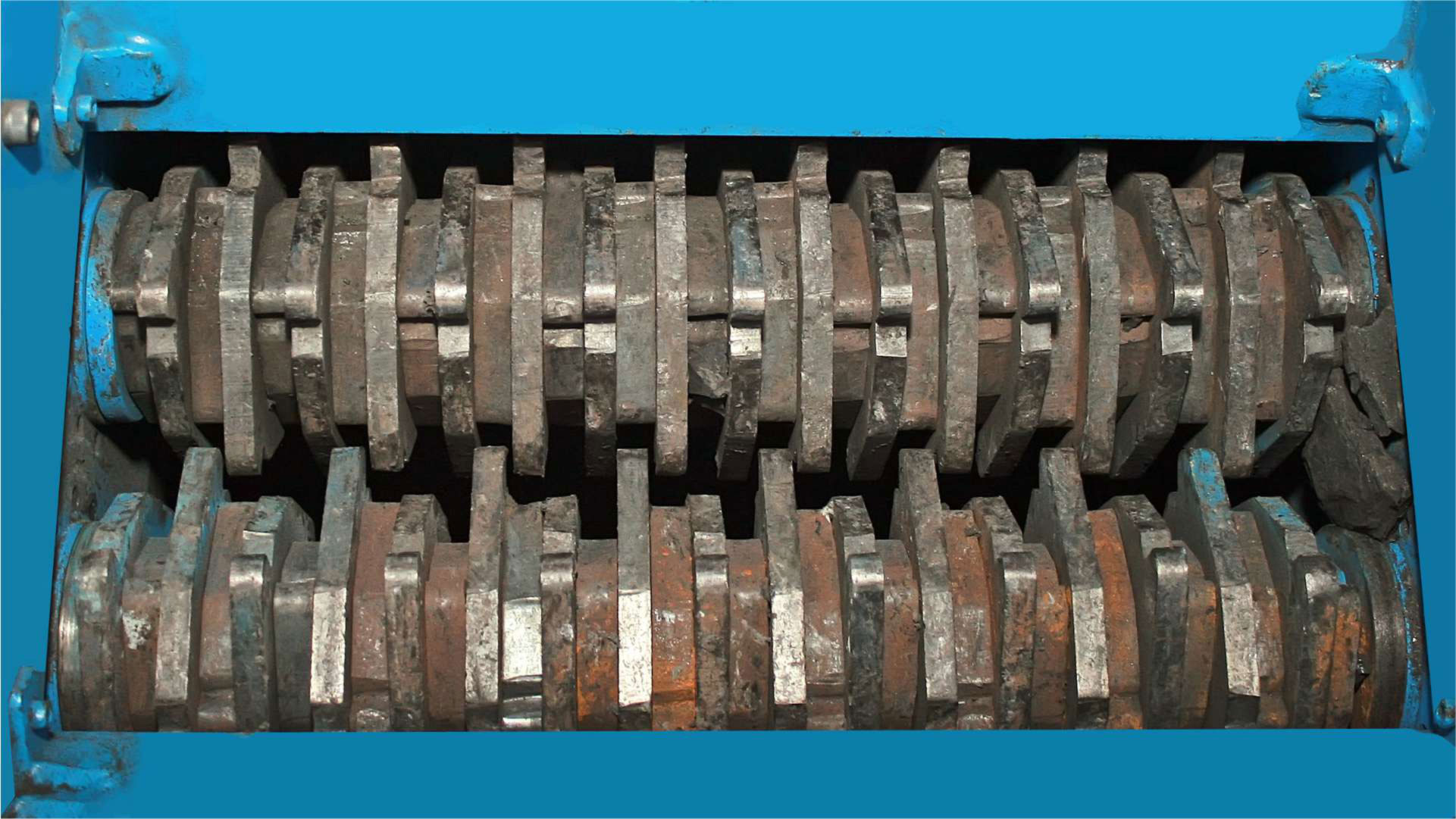

- The feed material is crushed by counter-rotating toothed rolls.

- Equipped with durable and wear-resistant teeth, on the crushing rolls.

- Toothed roll crushers are strong and most suitable for coal mine lab-scale crushing operation and have a long life, backed by our nationwide service network to keep your products in prime condition.

- Less generation of fines.

- High productivity, low cost per ton.

- Integrated crushing combs, allow a product feed of large lumps.

- Attains size reduction by shearing stress and pressure, generated by high torque at the crushing roll.

- Even wet and sticky coal samples are crushed and handled with ease.

- Great choice for primary and secondary crushing of different grades of coal of soft and medium-hardness.

| Feed Size | Output Sizes | Cycle Time in mins |

| Upto 230mm (-9″) | Upto 50 mm | 60 mins (1000 Kgs) |

| Upto 80 mm (~3.15″) | Upto 12.5 mm | 60 mins (250 Kgs) |

Input -230mm

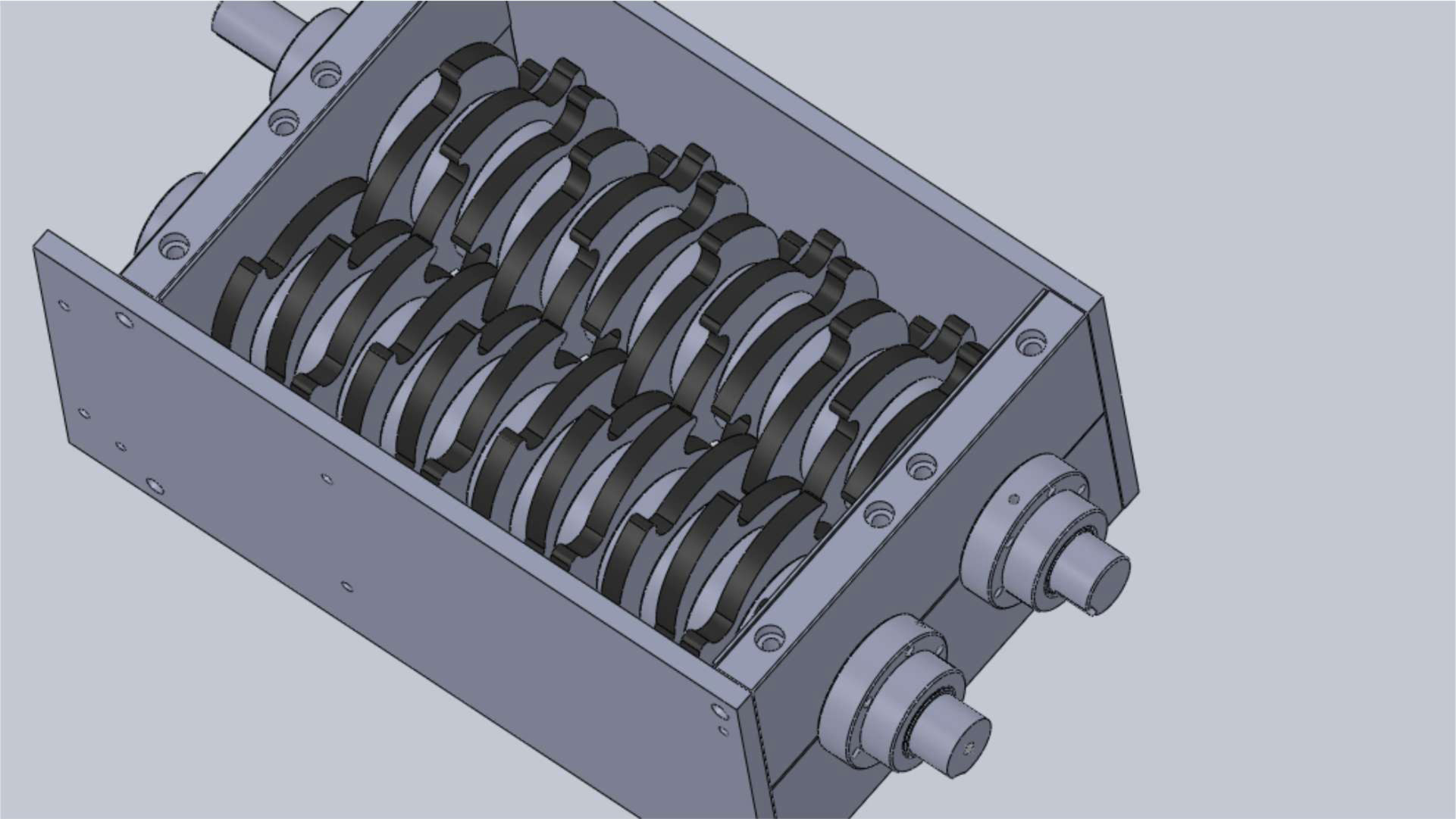

Toothed Roll Crusher Crushing Rolls