Pneumatic Sample Transportation Systems

Customisable Solutions

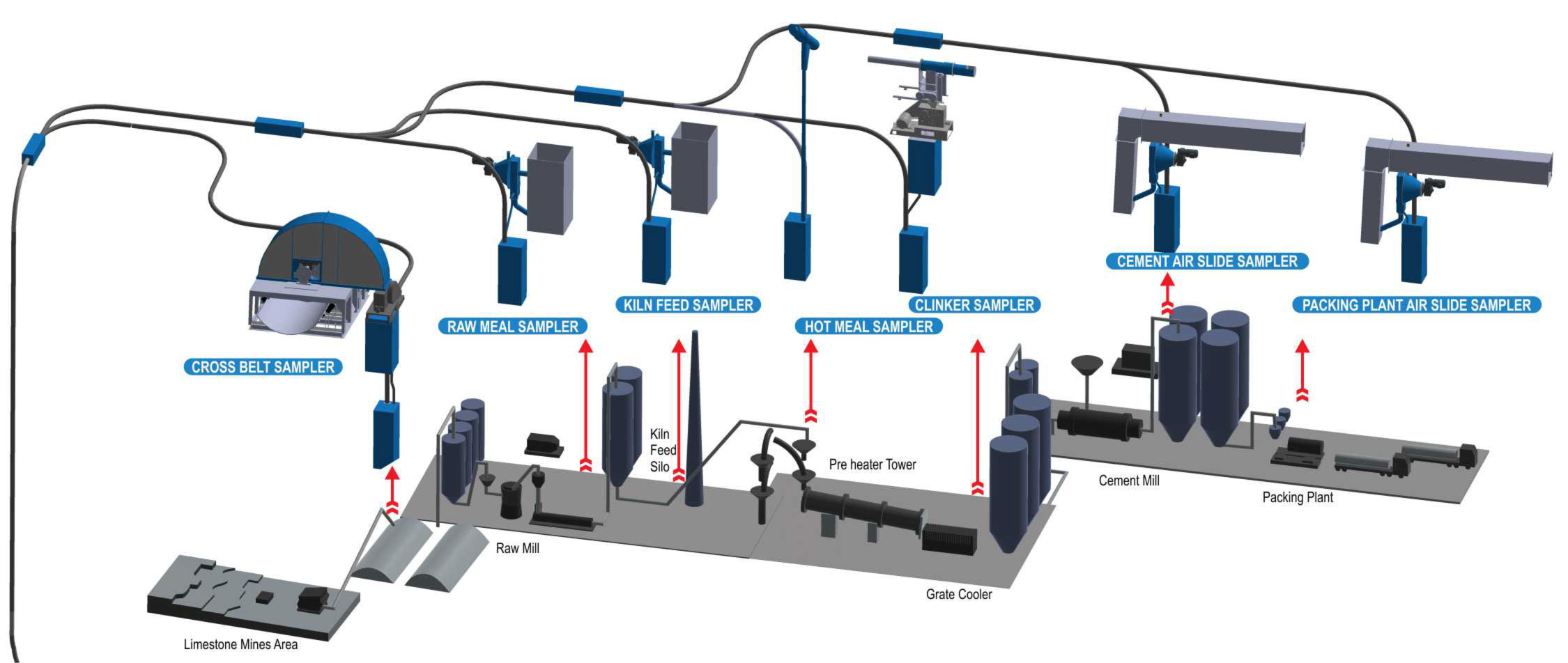

As a competent partner for providing pneumatic sample transportation system - Insmart has now ingeniously build a completely new technology of high-quality pneumatic sample transportation system for the sample bottle transportation services. This system best suites the auto sample caring needs of cement, iron and steel and aluminium manufacturing companies.

With our decades of experience, we have the necessary in-depth expertise that makes us a leading Indian innovator in process material sampling.

We at Insmart develop and manufacture our own plant components and provide fully automatic controls and software engineering. Thus, we are able to provide tailor-made, comprehensive solutions complete with consultancy, training and after-sales service for auto sample transportation systems.

We at Insmart develop and manufacture our own plant components and provide fully automatic controls and software engineering. Thus, we are able to provide tailor-made, comprehensive solutions complete with consultancy, training and after-sales service for auto sample transportation systems.

During standard operation the bottles are transported with up to 16 m/sec (60 km/h) through the transport tube network. The speed can be considerably reduced during the sample landing locations at sending and receiving stations. Here the sample bottles glide at a very low speed of only 2 to 3 m/sec. and this controlled transport condition allows the problem-free transport of laboratory samples and ensures that the bottles remain undamaged and intact for longer time.

Success through experience, know-how and service

All customer-specific solutions are based on the many years of experience and the expertise of our competent engineers and technicians. We offer complete solutions from one source, including consultation and support from our works.

Track and trace transports

The sample bottle path is equipped with tacking devices to identify, track and trace bottles in real time.

Minimize risk of contamination

The lids of the twin cap bottle are equipped with leak-resistant seals to prevent leaks or spillage of powders from the bottle during transport. Therefore, the insmart provided bottles can handle fine powders like raw meal kiln feed or even finer cement sample with great ease, minimizing the risks of spillages in the pneumatic tube system network running through the plant.

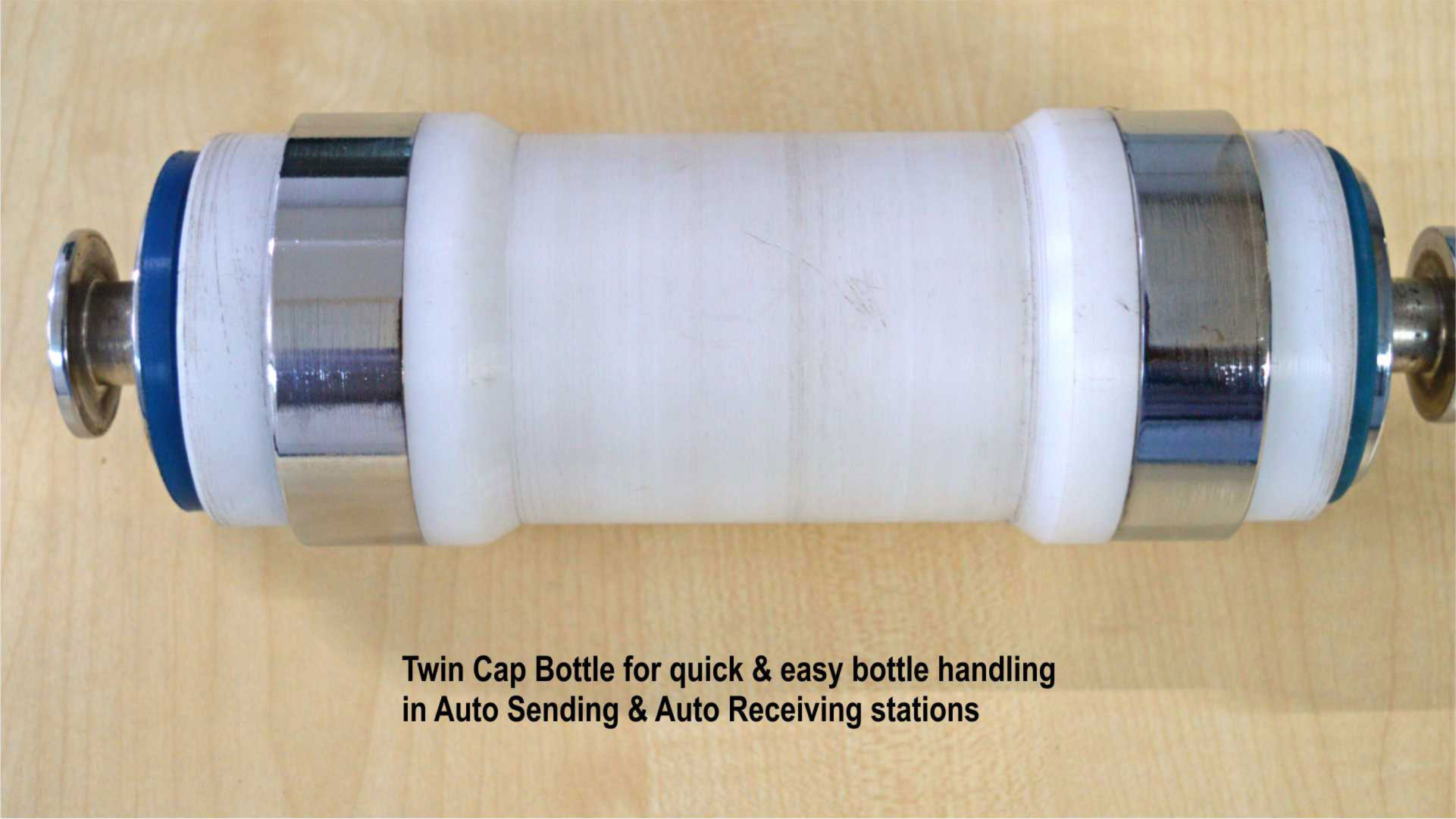

Unique TWO-caps-in-ONE Bottle Design: Leak-resistant and smart capping and un-capping arrangement.

The sample bottle with twin cap feature presents an innovative way of effortless opening, at the sending as well as receiving station without turning the bottle, thus simplifying auto handling and improving the turnaround times.

Both lids of the insmart design bottles are equipped with a slot for easy capping and de-capping in automated sending and receiving stations. It enables loading and unloading of the bottle without manual handling in dusty and low accessibility areas and in Robotic laboratories.

For a fully automated lab environment, the transportation systems is connected directly to the auto sending station at one end and auto receiving station at the other end in the robotic sample preparation laboratory.

Operational 24/7

The redundancy of blower lines guarantees an operational system around the clock without downtime.

Increase turnover time for analysis results

Increase sample analysis up to 16 to and fro sample bottle movement per hour

100% guaranteed bottle deliveries with bottle movement tracking

Full integration with robots in the automatic sample preparation lab

Enhanced Risk management

Linking logistical data: Lab data, sample type and time of collection, sending station and receiving station data for better traceability and integration with other plant systems

Zero-Risk Management: only authorised staff has access to stations.

It dramatically reduces manual transport tasks, shortens turnaround time, enables “lean” workflow processes and increases operational efficiency by redeploying personnel to higher value-add tasks.

Success through experience, know-how and service

All customer-specific solutions are based on the many years of experience and the expertise of our competent engineers and technicians. We offer complete solutions from one source, including consultation and support from our works.

Track and trace transports

The sample bottle path is equipped with tacking devices to identify, track and trace bottles in real time.

Minimize risk of contamination

The lids of the twin cap bottle are equipped with leak-resistant seals to prevent leaks or spillage of powders from the bottle during transport. Therefore, the insmart provided bottles can handle fine powders like raw meal kiln feed or even finer cement sample with great ease, minimizing the risks of spillages in the pneumatic tube system network running through the plant.

Unique TWO-caps-in-ONE Bottle Design: Leak-resistant and smart capping and un-capping arrangement.

The sample bottle with twin cap feature presents an innovative way of effortless opening, at the sending as well as receiving station without turning the bottle, thus simplifying auto handling and improving the turnaround times.

Both lids of the insmart design bottles are equipped with a slot for easy capping and de-capping in automated sending and receiving stations. It enables loading and unloading of the bottle without manual handling in dusty and low accessibility areas and in Robotic laboratories.