RI / RDI Equipment

The RI/RDI Test set up designed and manufactured by Insmart Systems used for the determination of the degradation index of Iron Oxides: Lump Ore, Sinter and Pellets. The equipment is designed and developed as per the IS 10823:1994 and The Indian Standard IS 10823:1994 harmonized with the ISO 4696 standard.

Reduction Degradation:

The size degradation of the iron bearing materials occurs because of reduction at 500 degree centigrade under Carbon Monoxide (CO) and Nitrogen (N2) atmosphere and related stresses introduced in the matrix due to phase changes. The cooled oxide material is tumbled for 300 revolutions In total. S1ev1ng with the test sieves having square mesh apertures of6.3mm, 3.15mm and 500 micron.

Test Apparatus:

1.Cylindrical Furnace – The Furnace is tube type, divided into three zones for uniform temperature control and attain desired sample temperature.

- Heating Element: Kanthal

- Furnace Skin Temperature: Below 50°C

2.Sample preparation

Iron Ore Sinter, Lump Ore, Iron Ore pellets are to be screened.

Sample size: +10mm to-12.5mm

Sample Quantity: 500grams ± 1.0 gram

Oven dry the sample for 2Hours at 105 ± 5 deg C

a)Sieves set- 2 Nos

Square mesh-12.5mm, 10mm, 3.15mm, 0.5mm.

b)Weighing balance- 1No

Capacity-1 Kg, Readable: 0.10 Grams

3.Gas Mixing Chamber

Gas mixing chamber for mixing of reduction gases along with gas drying and flow regulation.

Gas mixing chamber to mix maximum of4 gases. Flow rate of CO and N2: 20 LPM +/-1.0 LPM co:30% +/-0.5; N2: 70% +/-0.5

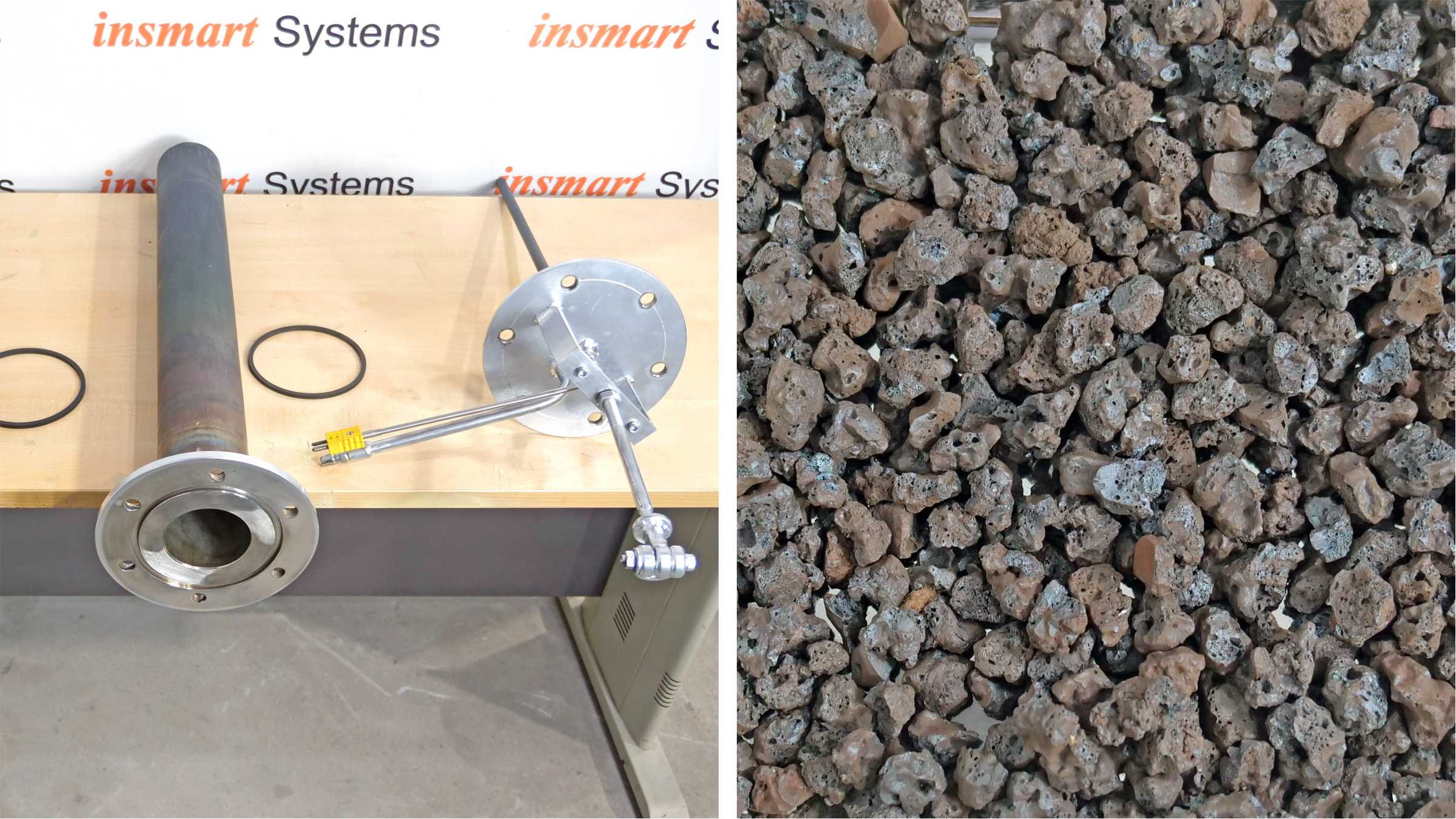

4.Reduction Tube – Reduction tube is made of non-scaling, heat-resisting Inconel to withstand temperature of 1000 deg C. The reduction tube has gas inlet and outlet points. Inside diameter of tube: 75+/-1.0mm.

5.Sample holder

Sample holder is made from INCONEL 600. It is equipped with a thermocouple to measure the temperature of the sample. The sample holder has a loose fitting and perforated bottom with Alumina balls for distribution of reduction gas.

- Online Electronic weighing balance – ±5.0 grams accuracy

Online weighing balance is installed for continuous online measurement of sample during reduction to measure the loss of sample due to gaseous reactions during reduction.

- Temperature control panel

Temperature control panel will assist in temperature regulation and automatic control of sample testing temperature during entire test duration.

- Tumbler drum

130mm internal dia vessel,

200mm length

30 +/-1 for rpm for 10 mins

- Gas Burning chamber

The reacted gas is burnt in a gas burning chamber. Gas burning chamber is equipped with electrical burner which maintains 700 deg minimum to ensure completer burning of Carbon monoxide to carbon dioxide.

- Ambient Air quality monitoring system

Online Carbon Monoxide and Oxygen monitors are installed in the testing area. The system will create awareness and help in taking appropriate actions to ensure personnel safety.

- Hoist Crane

One hoist crane is installed above for lifting, positioning of retort inside the furnace and removal of the same after the reduction test. It is hand operated. Additional features are inbuilt for RI Measurement.

- For REDUCIBILITY INDEX measurement of Iron Ores: Lump Ore, Sinter and Pellets, the temperature requirement of the sample is 950 deg C ±10 deg.

Reduction time is 3 hours.