Softening and Melting

Insmart Softening and Melting Apparatus is designed strictly conforming to BIS 9660 Standard. The Equipment is used for determination of softening and melting characteristics of Iron Ore/ Sinter/ Lump and Pellets. It simulates the softening characteristics of the feed material in the Blast Furnace.

It consists of a Cylindrical Container, Lower Stainless-steel pipe, Upper Graphite Ram, Upper Stainless-Steel Pipe etc.

Cylindrical Container:

The container opens at both the ends and is made of graphite, The dimensions of the cylinder are: ID = 50mm and L = 100mm. It also consists of a perforated bottom plate with 5 Holes which is also made of graphite. This graphite container fits to the lower stainless-steel pipe.

Lower Stainless-Steel Pipe:

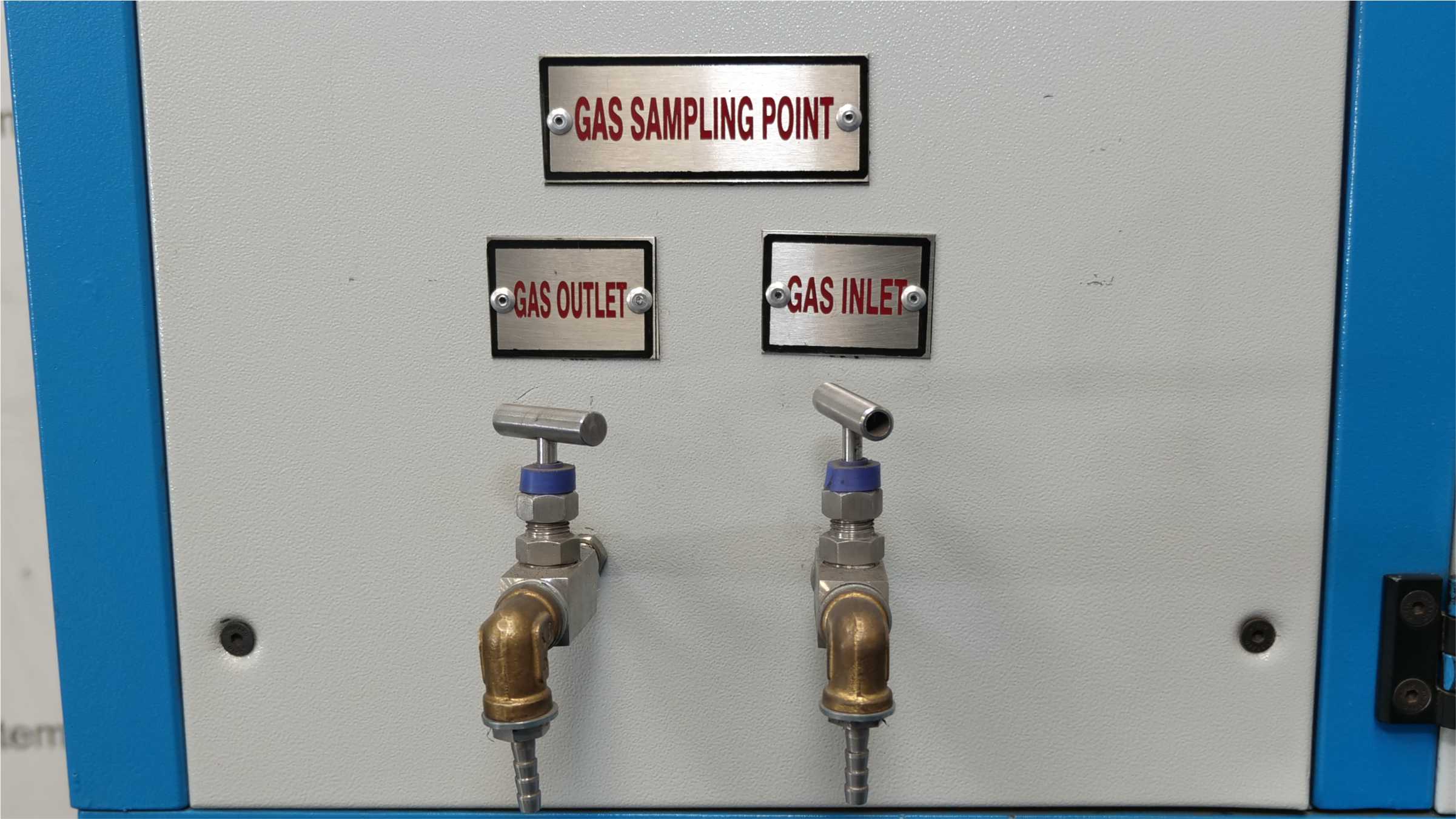

The lower Stainless-steel pipe fits tightly into the graphite bottom plate, and it is long enough to extend outside the furnace tube in the ambient. The gas line is also connected to the manometer and its pressure is also recorded throughout the test.

Upper Graphite Arm:

After the graphite cylinder is fitted with alternate layers of coke, iron bearing material / Al2O3 balls to a height of 90 mm, a graphite pressure ram perforated axially like the bottom plate is placed over the upper Al2O3 ball layer. The central hole will be used for introducing thermocouple.

Furnace:

Max Temperature: 1300°C

Heating element : Nichrome / Kanthal

Heating rate: 21° C / minute (as per standard)

Furnace Type: Split Type

The apparatus includes a water gauge for continuous recording of pressure of the inlet gas, gas pipettes / infrared gas Analyzer for analysis of the inlet and outlet gas and a pointer attached to the top stainless-steel cap for indicating the setting due to softening, during reduction under load, as stipulated in IS: 9660.