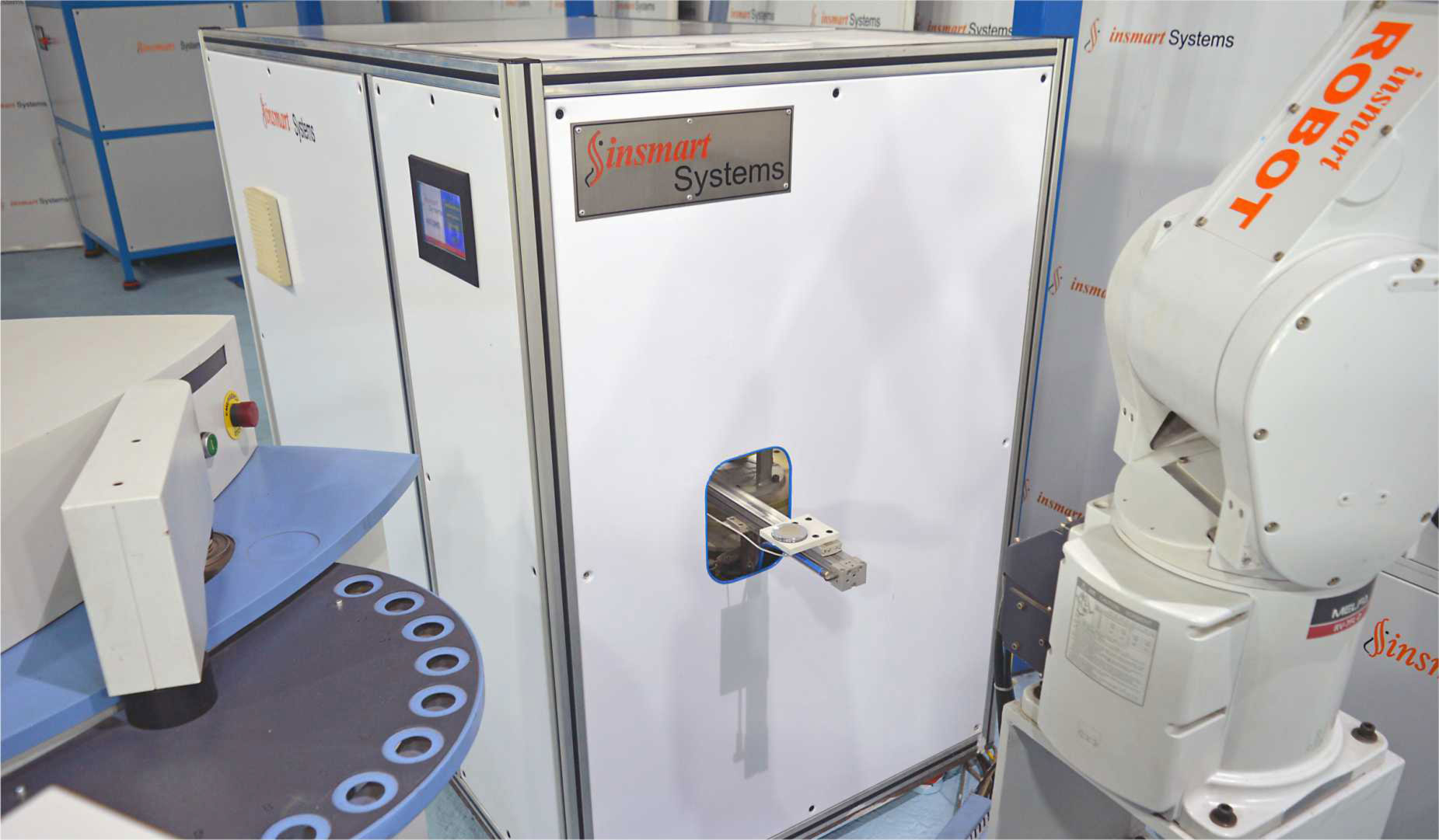

Semi Automatic – Grinding & Pelletizing Units with Robotic integration – Auto Combo B

Insmart Auto-Combo B is a CE Certified fairly advanced auto grinding and pelletizing unit. It is compatible to the Robotic lab and an ideal fit for integration with XRF/XRD and other analytical equipment like particle size analyzer.

Its software identifies the grinding and pelletzing method from the ID and based on material type, it automatically performs the right amount of grinding and offers right amount of compaction pressure for getting the desired results.

ID specific grinding & pelletizing operation

Operating parameters are Sample ID based. This eliminates the chance of a particular sample result being erroneously tagged to the wrong sample ID. The Auto-Combo software automatically correlates the sample ID and sample results and stores the sample data together with the rest of the analysis in an open database.

The database is updated in real-time and can be easily connected to the automatic raw mix feeder control system or any other software or plant ERP for example.

Utilizing right sample quantity and controlling cross contamination

Volumetric dosing and auto binder tablet feeding is used in Auto-Combo-B. Ensuring optimum quantity is ground and homogenized with binder tablets before auto transfer for pellet making.

Pre-programmed auto self cleaning and gargle cycle of grinding media and pelletizing set is built in for all new samples; a unique system to grind sample & eliminate cross contamination.

Secondly, the unit performs self cleaning after every grinding and pellet making cycle. This action is performed by using very powerful compressed air jets coupled with powerful suction cleaning to free the grinding and pelletizing chambers from sample traces.

Auto Grinding and Auto Pellet making

Pre set Auto grinding based on sample type and dosed quantity Auto compaction using the pre defined tonnage and compaction time.

Self contained stacks of Pellet rings and Binder tablets

The equipment is provided with a stack of substantially high number of reusable ( 25 Nos.) pellet rings so that the auto pellet ring feeding mechanism never goes out of rings even if a few rings are in the XRF/XRD analysis cycle. The system accepts analyzed sample rings after auto pellet breaking and cleaning.

Here, the Auto Combo B commands the XRF system to return the ring on the same conveyor which delivered the sample ring to it. On receipt the Auto-combo B “de-pelletizes” the ring and store it in its ring storage system only to be used for the next cycle.

Similarly, a storage tank for binder tablet stores the weekly stock and submits a pre decided quantity to the vibratory cup mill bowl.

Auto check on structural integrity & surface cleaning

Auto pellet surface cleaning with directed jets of compressed air and suction pressure eliminates superficial dust on both sides of the compacted pellets.

Similarly the system Auto checks on structural integrity of pellets. If strong, Auto-Combo loads it on a small conveyor to be carried to the XRF system.