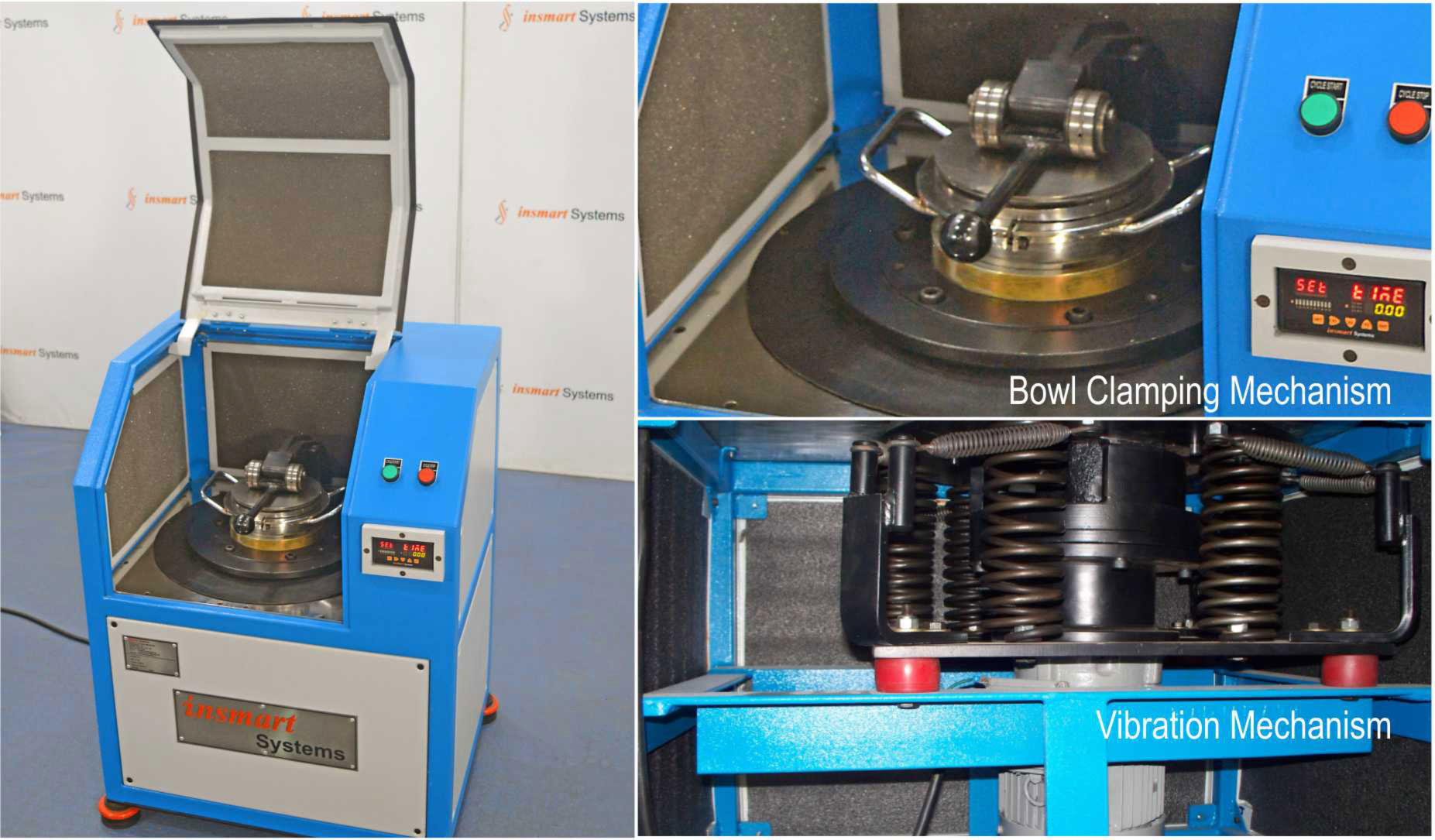

Vibratory Cup Mills – VCM

Vibratory cup mills are suitable for the grinding of even harder minerals like Slags, Ferro alloys and other materials upto a fineness of 38 microns. The high speed of the drive motor and the gyratory motion of imbalance mass enables even hard material to be ground within a very short time.

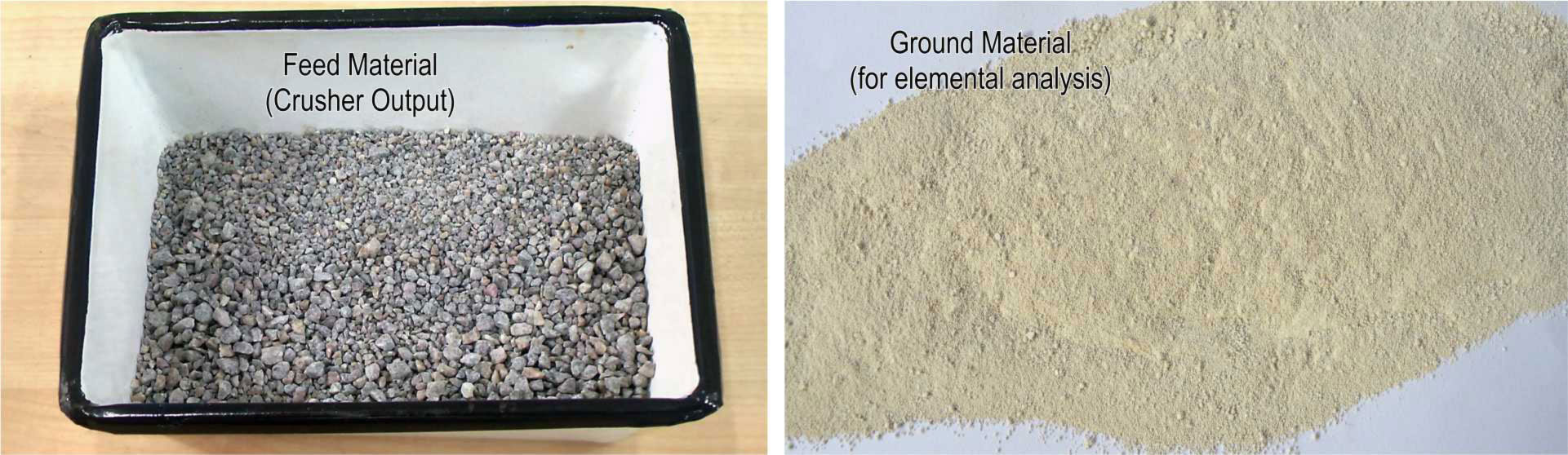

It is meant for most efficient lab scale pulverizing operation in mining, metallurgy, cement, steel, aluminium, ceramics industries and the ground product is ideal for instrumental analysis using x-ray fluorescence analysis. The equipment performs fine grinding of dry as well as wet laboratory samples with equal ease.

Ideal for exceptionally rapid grinding of extremely hard, Brittle and soft materials down to laboratory fineness.

Working Principal of Vibratory Cup Mill:

The Vibratory Cup Mill brings about an impact of the hammer and/or the ring (grinding media) on the grinding materials inside the bowl this causes the size reduction. The collision intensity depends on heaviness and differential speed of the grinding media. The imbalance mass in the motor drive creates vigorous motion of the bowl and the grinding media. The equipment attains maximum impact from the very start of the grinding to attain most optimal and repeatable results in few minutes.

Grinding bowls are used for a range of applications, with capacities of 50 ml, 150 ml. Hardened steel, Stainless steel and Tungsten carbide bowls are designed for easy handling where the operator simply clamps the bowls and starts the grinding operation.

Insmart vibratory cup mills are fully insulated against noise and have safety cut-outs for operator protection. The dust and noise pollution at the workplace is therefore substantially reduced.

Insmart vibratory cup mills are high-quality, precision engineering products with compact dimensions and are therefore ideally suited for QC lab scale grinding operations.

The design of the machines corresponds to the current accident prevention guidelines.

Highlights of Grinding Environment:

150 ml bowl is fed with input material size of upto 8 mm, suitable for a variety of sample types.

Exceedingly quick grinding (30 seconds to 3 mins).

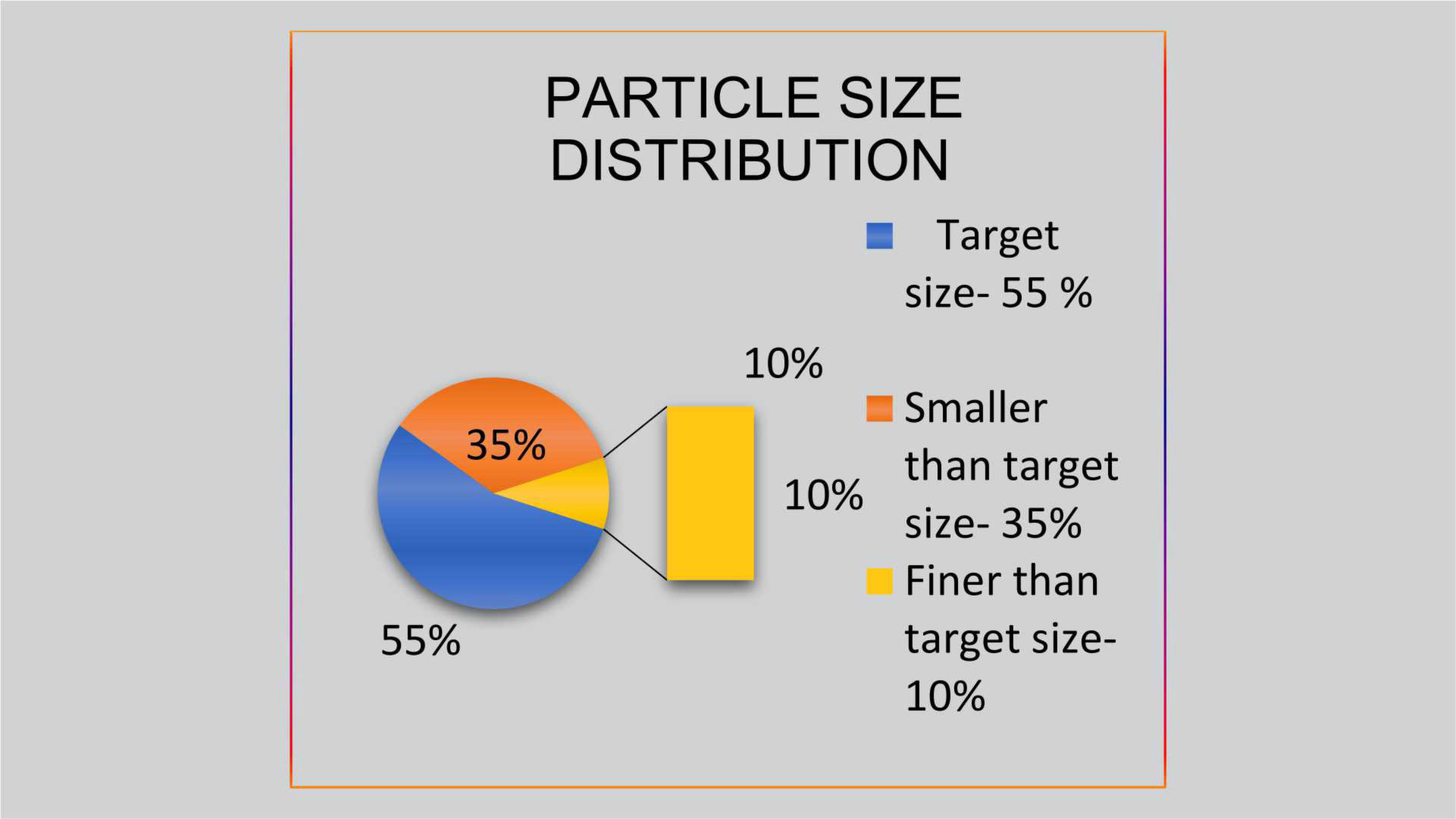

Fast grinding achieves the desired particle size in the range of 100 to 325 mesh.

Material of Construction: Grinding cup and rings are made from hardened steel, Tungsten Carbide, Agate or stainless Steel (depending upon material to be ground) provides improved analytical results as it gives reduced sample contamination.

Easily operable pulverizing set.

Dry & wet pulverizing.

VCM Main Features:

Programmable Grinding: Grinding cycle time can be completely preseted. Thus, required fineness is achieved even under intermittent power supply conditions.

Programmable cycle time setting is possible to suite the material fineness.

Changeability in Bowl location plate: No change of bowl location plate is required and bowl sets of 50ml to 250 ml can be placed on the same bowl location plate.

Four Bowl Simultaneous Grinding: In case of multiple material grinding requirements, 4 Bowl VCM provides the facility of grinding 4 different materials at the same time. This option is available only with 50 ml bowls.

Safety Features:

Over Load Tripping:

In order to counter power surges Motor drive is provided with additional protection through OLR- trip.

4 Pole MCB with reliable circuit breaker is also provided for additional machine safety during power surges.

Door sensor:

Material Grinding is done in an enclosure fitted with a door to load & retrieve the material. Thus, grinding is performed in a protected area.

In case the door is opened while machine is in operation, the machine is provided with suitable sensors that stop the machine in order to avoid any possible accident.

Flexibility in Grinding Output

Range of size reduction from -8 mm to 38 microns is achieved by faster and more efficient grinding(material dependent)

Programmable cycle time setting is possible to suit the material fineness

Easy Replacement of Bowl and Bowl location plate

| Purpose | Pulverizing for laboratory use | ||||

| Mounting Type | Floor mounting | No foundation required | |||

| Working Principle | Friction | ||||

| Maximum Feed Size | upto 8 mm | ||||

| Output Size (adjustable) | Start Range : ≤ 100 mesh | End Range : ≤ 325 mesh | Cycle time: 30 sec to 3 mins for 20 to 60 gm sample (150ml bowl set) | ||

| Throughput at usual Product size | 15-20 samples per hour, per bowl | ||||

| Pulverizing materials | Bauxite, Clinker, Coal, Coke, Concrete, Corundum, Geological ores, Glass, Granite, Graphite, Laterite, Limestone, Iron ore, Quartz, Silicates, Slag, Ferro alloys. | Pulverizes materials with medium to substantially high hardness and brittleness. | |||

| Motor Drive | Motor Power : 1.5 kw | 2HP Motor | RPM : 1440 | Volts: 415 | 3 Phase induction Motor |

| Required Power | 3 phase neutral + earthing through 10 amps 4 Pole MCB

[Red, Yellow, Blue, Neutral, Earthing] |

||||

| Machine Size (in millimeters) | Length: 600 | Width: 720 | Height : 950 | ||

| Weight (Kg) | Machine: 230 | Wooden Box: 80 | Total Machine: 310 | ||

VCM – Range of Grinding Bowls

VCM – Input – Output

| VCM Bowl Materials | Main Component of the materials | Material suitability | Bowl Resistance to abrasiveness | Grinding Time |

Output Range |

| Hardened Steel | Fe – Cr | Slag, Iron ore, Clinker, Bauxite, Laterite, Quartz, Granite, Gypsum, Limestone, Pigments, Carborundum, Embrittled materials like high density plastics | superior | 1-3 mins | 100 to 325 mesh [suitable for XRF / XRD and or wet chemical analysis] |

| Tungsten Carbide – Coated | Fe – WC | Coke, Coal | Excellent | 1-2 mins | Upto 72 mesh |

| Tungsten Carbide – Lined | WC | Ferro manganese, Ferro silicon, Ferro chrome | Excellent | 1-5 mins | Upto 325 mesh |

| Stainless Steel | SS | Tablets, Salts, Fertilizers | Superior | 1-3 mins | 325 mesh |

| Material | Material Type |

| Slag, Ferro alloys, Granite , Feldspar, Quartz, Iron ore, Sponge iron | Hard-abrasive |

| Clinker, Quartz, Rock, Bauxite, Ceramics, Carborundum | Hard-brittle |

| Glass, Calcite, Coal, Coke, Tablets, Fertilizers | Medium-hard |

| Gypsum, Salts, Graphite, Pigments, Mica | Soft |

| Alloys, Ceramics, Salts, Tablets, Silicon Carbide, Silicon nitride, Coke, Coal, Embrittled e.g. high density plastic | Brittle |

| Elemental & Phase Analysis |

For preparing ground samples in a less mill operation time without any undesired grinding media grazing. Application areas: Mined material processing industries like: Iron & Steel, Cement, Glass, Ceramics, Material developmental R & D Labs |

| Metallurgy | For pulverizing cast iron samples or blast furnace slag to establish additives application |

| Mining, Cement and Iron & Steel industry | Meant for processing minerals or ores for physical or chemical analysis |

| Ceramics industry | For grinding lumpy samples to produce raw powder to determine

Calcium carbonate and magnesium oxide-content |

| Earth Sciences | Meant for preparing samples for chemical/elemental analysis for soil testing purposes, bore hole samples |

| Volume | Useful Capacity (sample quantity) | Grinding Media |

| 50 ml | 10 gms by weight for materials of specific gravity upto 1.6 gms/mc3 | Bowl & Hammer |

| 100 ml | 30 gms by weight for materials of specific gravity upto 1.6 gms/mc3 | Bowl with hammer & Ring |

| 150 ml | 50 gms by weight for materials of specific gravity upto 1.6 gms/mc3 | Bowl with hammer & Ring |

| 250 ml | 70 gms by weight for materials of specific gravity upto 1.6 gms/mc3 | Bowl with hammer & Ring |