Air Slide Sampler

Exclusively designed to extract selective sample from the material flow and provide desired material representativeness.

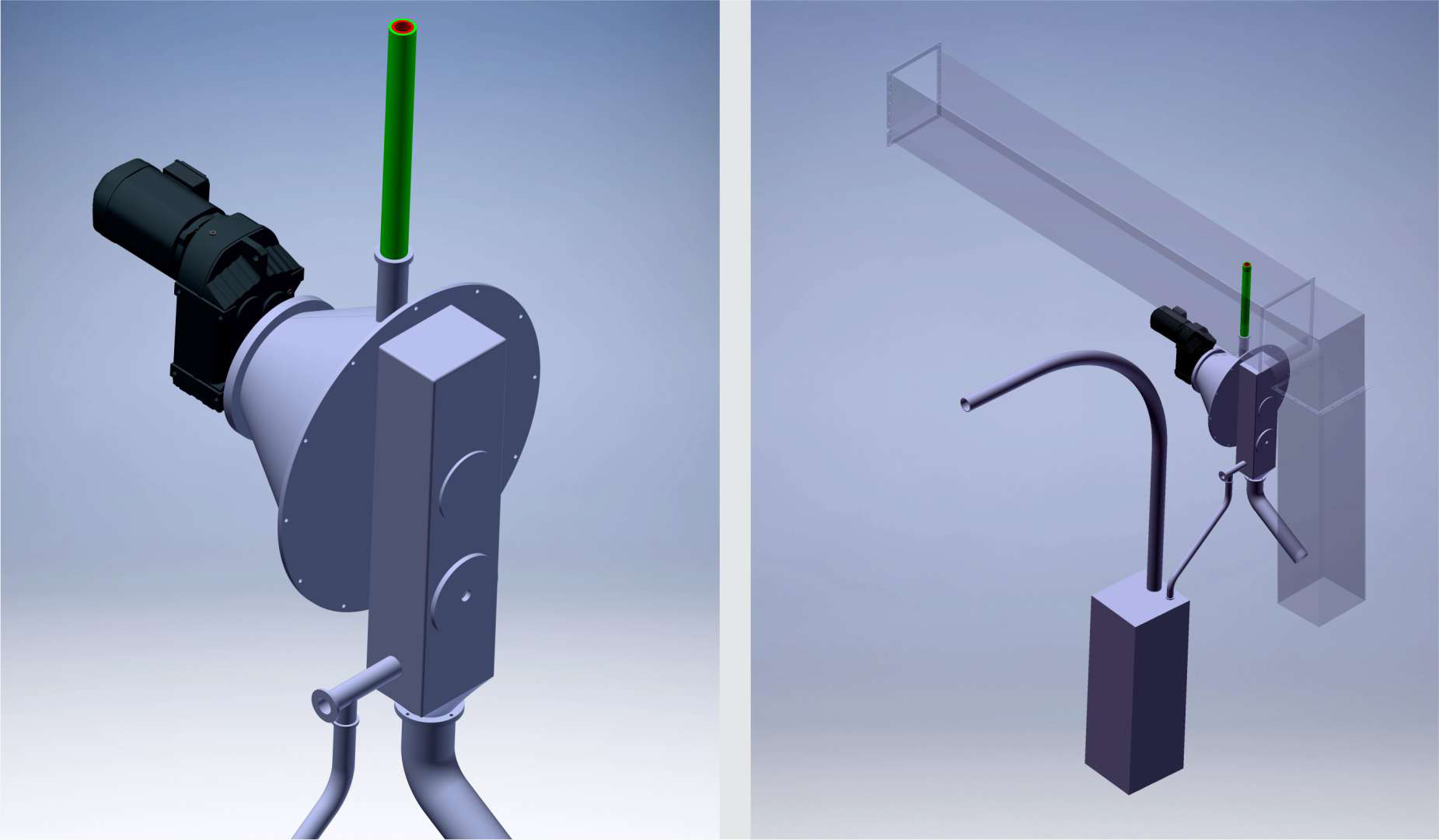

The sampling system consists of two sampling arms located inside the Air Slide and they directly intercept the material flow. Both the arms have slots cut in them parallel to their center axis.

The outer pipe can rotate about its axis by 180 deg. through rack and pinion arrangement. During sampling, the slot in outer pipe faces the flows of the material in the air slide.

The inner pipe does not rotate and the slot of the inner pipe, always faces the direction of the material flow. When not sampling the outer pipe is rotated by an external, pneumatically driven, rack and pinion such that the slot of the external pipe is facing away from the direction of flow of material.

This sampling system can be used to sample powdery material from the Air Slide. The duration and frequency of sample collection is fully programmable.

When not sampling the sample entry gate is closed and the outer pipe is rotated by 180 deg such that the outer slot does not see the flow of material.

Air Slide Sampler samples powdered material e.g cement, flowing in the air slide.

Samples at a desired interval.

Easy to install and automatic operation.

Compact and low maintenance.

Designed to eliminate product pilferage against air pressure.

Minimum intrusion in path of cement flow.

Rugged Steel and polypropylene construction.

Air Slide sampling arms.

Homogenizer coupled with sample dispenser.

Sample conveying system.

Reject Material handling system to deposit the material in the main stream.

Onsite sending station.

The homogenizer mixes the material using two paddles.

The paddles are operated using a geared motor.

The sample dispensing system consists of a motor driven sampler.

This secondary screw samples the primary collected material and transfers the homogenizer output into the “sample dozing port”.

All other components of air slide sampler which includes the secondary sampler, sending station and excess material handling systems are identical to the screw sampler.

| 1 | Material | Raw meal, Kiln Feed, Cement, Feldspar, Silica |

| 2 | Sample collection | Intermittent / Continuous |

| 3 | Mixing/ Homogenizing | Continuous |

| 4 | Sample Drawl Frequency | 30 minutes to 120 minutes ( programmable) |

| 5 | No of bottles | 2 |

| 6 | Drawn composite sample qty | Approx. 200 gms per hour (in bottle) |

| 9 | Mixing bin capacity | 42 liter |

| The design of the machine complies with the applicable accident prevention & regulations. | ||