Robotic Sample Preparation Labs

Cement Labs with Robotic Sample Preparation Systems

Insmart systems automated and robotic sample preparation systems are custom built and they are best suited for cement grinding units as well as multi-kiln cement plants.

An investment with a quick returns

Insmart integrated auto sampling, auto transportation and integrated robotic labs provide complete end-to-end sampling to analysis solutions using advanced robotics sample handling technology for process material testing.

Insmart Robotic Labs have the following distinct advantages:

Extremely rapid sample preparation with unparalleled consistency.

Elimination of human involvement in day to day operations. Thus, eliminating human errors.

Comprehensive sample traceability from collection to analysis.

Synchronized process control with high reliability .

Fully programmable data interpretation parameters to suit every plant.

Insmart Robotic Systems increases operation health and safety of employees and eliminate heavy lifting and working in dusty environment.

Personnel are also isolated from hazardous zones/materials. Thus, improving personnel safety.

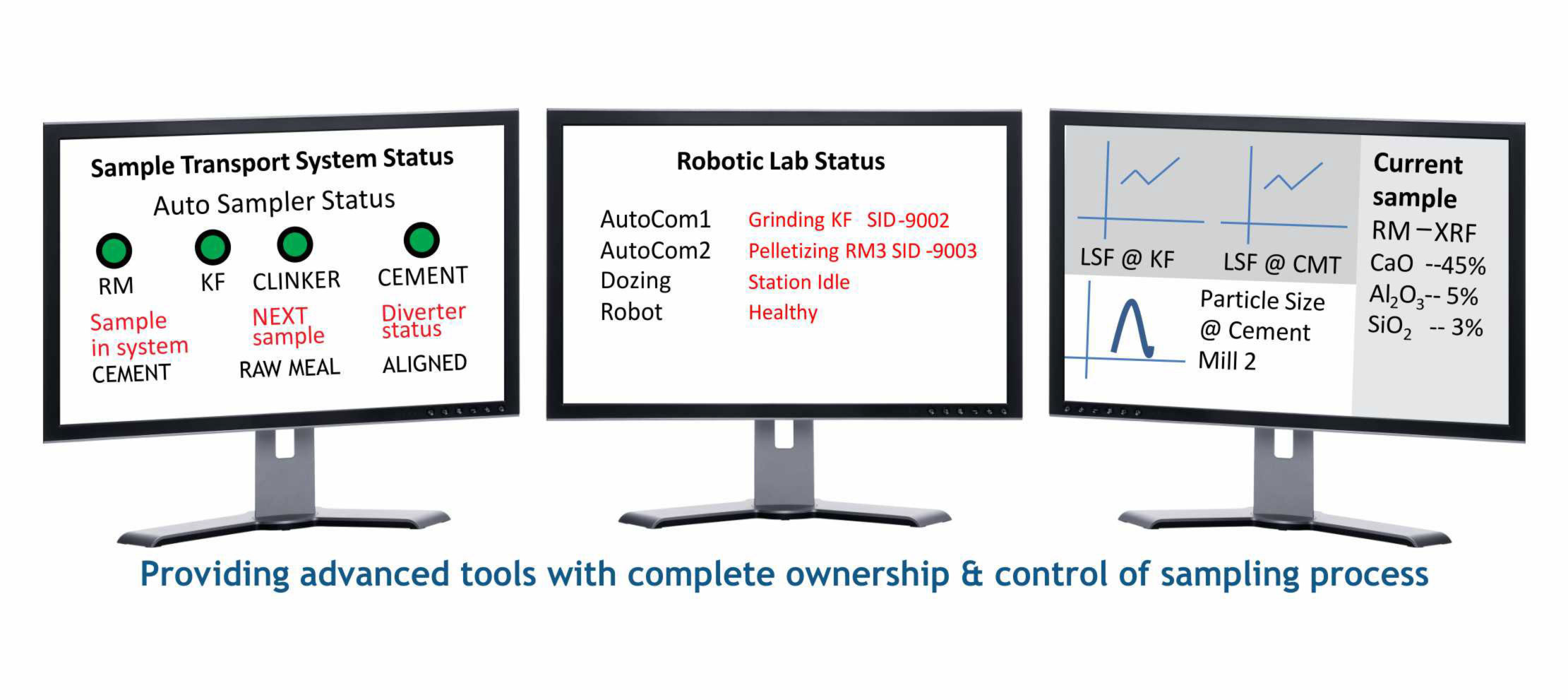

Automated Samplers and Sample Transportation systems can deliver reliable samples for analysis every hour or every half an hour from various sampling points like Raw Mill, Kiln Feed, Clinker (post grate coolers), Cement mill outputs and Packing silos without any manual intervention or interferences.

Automated Robotic lab handles the sample preparation and sample analysis with zero chance of errors and works with 98% availability.

The Automatic cement laboratory setup includes:

Automatic Sampling Systems

Automated Sample Transportation Systems

Automated Robotic Sample Preparation Systems

Analytical Equipment System integration

Seamless integration with plant softwares

Our Automation facilitates speedy and accurate analysis data availability for quick process control of following parameters:

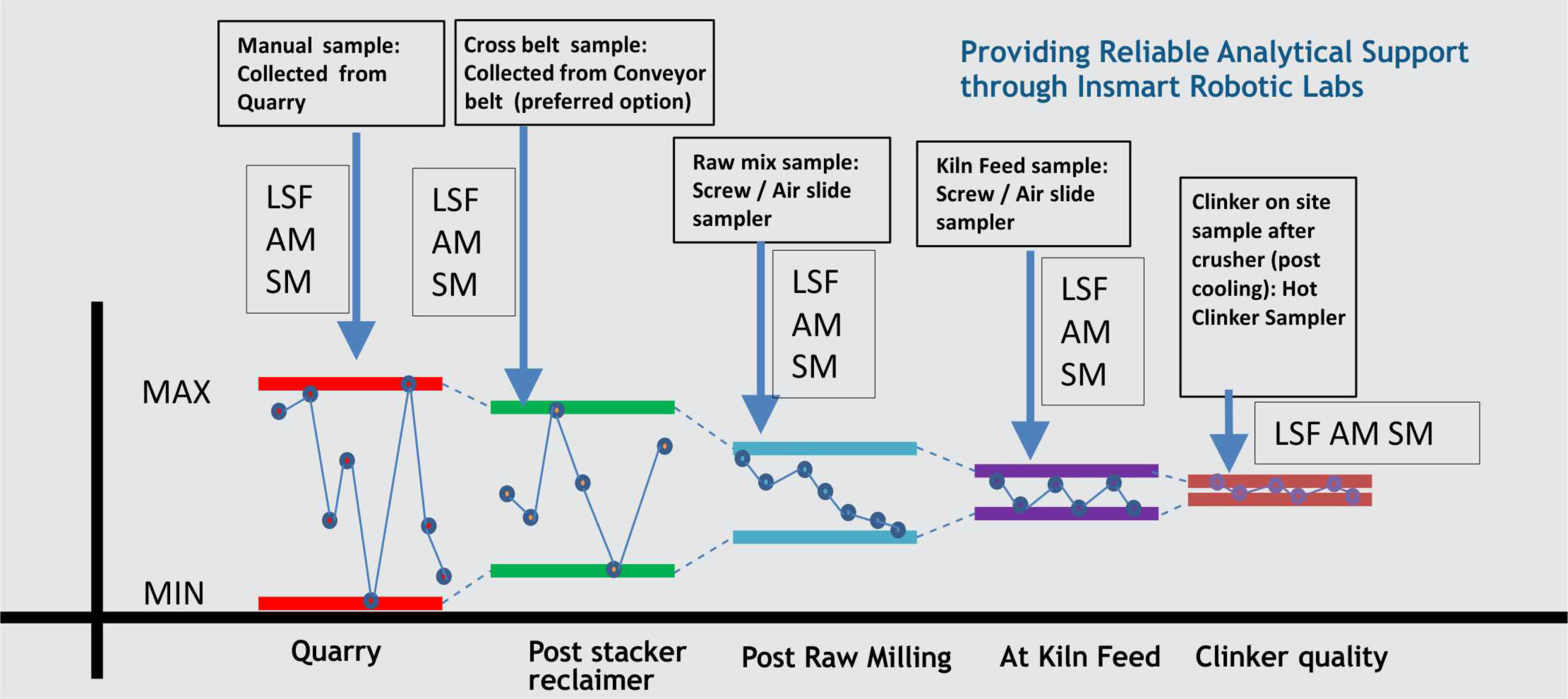

1) LSF, AM and SM* monitoring:

Monitored at Quarry

Pre blending silo

Post Raw milling, Kiln feed, Clinker and Cement stage

2) Free lime monitoring of Clinker:

Kiln performance

Burnability

3) Clinker phase monitoring:

Kiln performance and clinker quality

3) Dynamic particle size monitoring of:

Raw Mill output

Cement Mill output.

*LSF : Lime Saturation Factor, AM: Alumina Modulus, SM: Silica Modulus

Insmart Advantage:

Boosting Cement manufacturers operating performances by minimizing LSF, AM and SM variation from quarry stage sample analysis to clinker stage in real time.

Insmart Auto sampling Systems help reduce the variation as the process material tends to move towards the product stage (refer graphical representation above).

Smaller difference between Maximum and Minimum leads to better cement quality.

Insmart is a machinery manufacturer with in house sampler, sample preparation and robotic sample preparation expertise.

Other suppliers outsource machine manufacturing and this leads to higher equipment cost to the end customer.

Direct Project execution between Insmart and customer. No consultant or middle men involved. Thus, offering clear understanding of scope of supply and lower prices for the same functionality.

1. Robot for articulating the sample bottle, sample rings and other articulation needs.

2. Autocombo-B for complete automation of sample preparation.

3. Automated sample Bottle Receiving Station from Pneumatic Sample Transportation System.

4. Automated Sample Homogenization and Sample Division Unit for preparing bi-hourly, shift average and day average samples.

5. XRF/XRD system controlled by Insmart Automation Software.

6. Conveyor for pellet delivery between Auto combo-B, Robot and XRF/XRD units.

7. A glass partition wall to keep the XRF/XRD unit away from sample preparation system.

8. Provision for including other sample characterization systems such as Particle size analyzers, Free lime analyzers.

We provide ownership of Software and Automation of Robotic Systems to the customer.

Provide Perpetual license to the customer with freedom to upgrade the host computer, Provide a license copy every time the customer upgrades to a new computer system. Licenses do not expire till the customer is using the equipment. Thus, offering a huge cost advantage over the foreign suppliers.

Flexibility in supply of Full Automation

Automated samplers and the sample transportation system can be obtained in the second phase.

Flexibility to split the procurement of entire system over a two or three years.

Insmart Systems has been a quality control equipment manufacturer for last 25 years. Over the years we have graduated to the manufacturing of automatic systems. Thus, we are best placed in understanding the customers requirement and provide most suitable sampling automation for the end customer.

Comprehensive system for product QC

Follow ISO quality standards for manufacturing products of specified quality.

India’s only manufacturer of robotic labs and automated sample preparation systems for cement and steel plants.

Robotic Lab Functionality:

1. Sample Introduction: Receive sample bottles from automated Pneumatic Sample Transportation System and sample identification.

2. Sample Extraction: De-cap the bottle and extract the sample from it.

3. Sample division: Divide the bottle sample volumetrically for:

Sample preparation for XRF/XRD.

Day Average, Shift Average sample storage.

Sample for Particle size analyzer / other analyzers.

4. Sample Preparation: Automatic grinding and Pelletizing of each sample. Sending and receiving of pellet rings to XRF / XRD.

5. Sample XRF Analysis: Control and sequencing of XRF operations.

6. Sample for Particle Size analysis: Control of Particle size analyser.

7. Dust Extraction: Excess sample handling and also handling of material from analyzed pellets.

8. Day Average, Shift Average: Drawing a representative sample from hourly samples.

9. Cleaning of contact surfaces: All contact surfaces in Autocombo and cups that handle the samples are cleaned using high pressure air jets.

Constant updation of real-time data allows supervision of variances. It also enables:

| VCM Bowl Materials | Main Component of the materials | Material suitability | Bowl Resistance to abrasiveness | Grinding Time |

Output Range |

| Hardened Steel | Fe – Cr | Slag, Iron ore, Clinker, Bauxite, Laterite, Quartz, Granite, Gypsum, Limestone, Pigments, Carborundum, Embrittled materials like high density plastics | superior | 1-3 mins | 100 to 325 mesh [suitable for XRF / XRD and or wet chemical analysis] |

| Tungsten Carbide – Coated | Fe – WC | Coke, Coal | Excellent | 1-2 mins | Upto 72 mesh |

| Tungsten Carbide – Lined | WC | Ferro manganese, Ferro silicon, Ferro chrome | Excellent | 1-5 mins | Upto 325 mesh |

| Stainless Steel | SS | Tablets, Salts, Fertilizers | Superior | 1-3 mins | 325 mesh |

| Material | Material Type |

| Slag, Ferro alloys, Granite , Feldspar, Quartz, Iron ore, Sponge iron | Hard-abrasive |

| Clinker, Quartz, Rock, Bauxite, Ceramics, Carborundum | Hard-brittle |

| Glass, Calcite, Coal, Coke, Tablets, Fertilizers | Medium-hard |

| Gypsum, Salts, Graphite, Pigments, Mica | Soft |

| Alloys, Ceramics, Salts, Tablets, Silicon Carbide, Silicon nitride, Coke, Coal, Embrittled e.g. high density plastic | Brittle |

| Elemental & Phase Analysis |

For preparing ground samples in a less mill operation time without any undesired grinding media grazing. Application areas: Mined material processing industries like: Iron & Steel, Cement, Glass, Ceramics, Material developmental R & D Labs |

| Metallurgy | For pulverizing cast iron samples or blast furnace slag to establish additives application |

| Mining, Cement and Iron & Steel industry | Meant for processing minerals or ores for physical or chemical analysis |

| Ceramics industry | For grinding lumpy samples to produce raw powder to determine

Calcium carbonate and magnesium oxide-content |

| Earth Sciences | Meant for preparing samples for chemical/elemental analysis for soil testing purposes, bore hole samples |

| Volume | Useful Capacity (sample quantity) | Grinding Media |

| 50 ml | 10 gms by weight for materials of specific gravity upto 1.6 gms/mc3 | Bowl & Hammer |

| 100 ml | 30 gms by weight for materials of specific gravity upto 1.6 gms/mc3 | Bowl with hammer & Ring |

| 150 ml | 50 gms by weight for materials of specific gravity upto 1.6 gms/mc3 | Bowl with hammer & Ring |

| 250 ml | 70 gms by weight for materials of specific gravity upto 1.6 gms/mc3 | Bowl with hammer & Ring |