Mechanized Auger Sampler

Automatic equipment for extracting samples from trucks and railway wagons

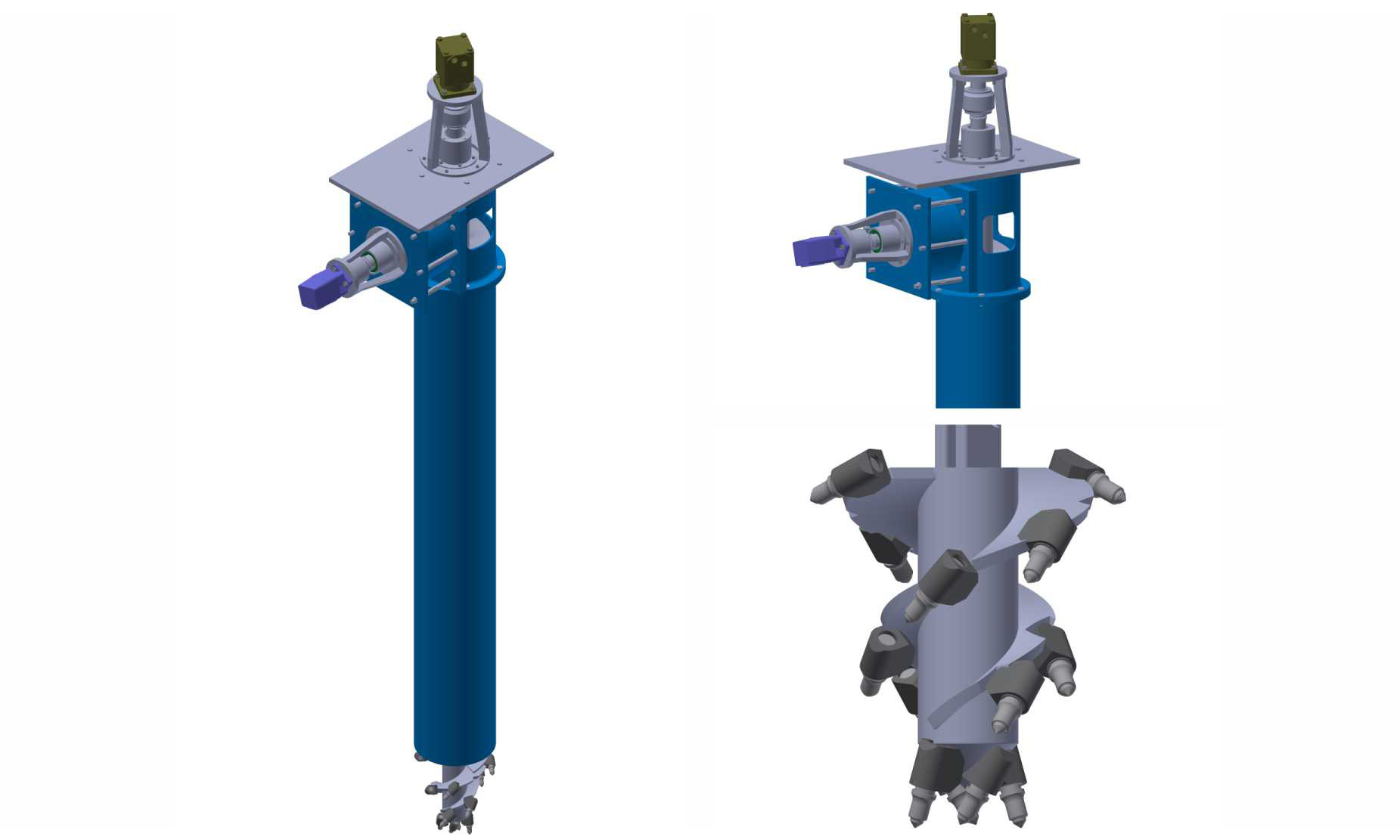

Due to high level of heterogeneity in the type of raw materials received in plants, Insmart has designed extremely powerful Auger samplers which collect samples using hydraulically operated drives.

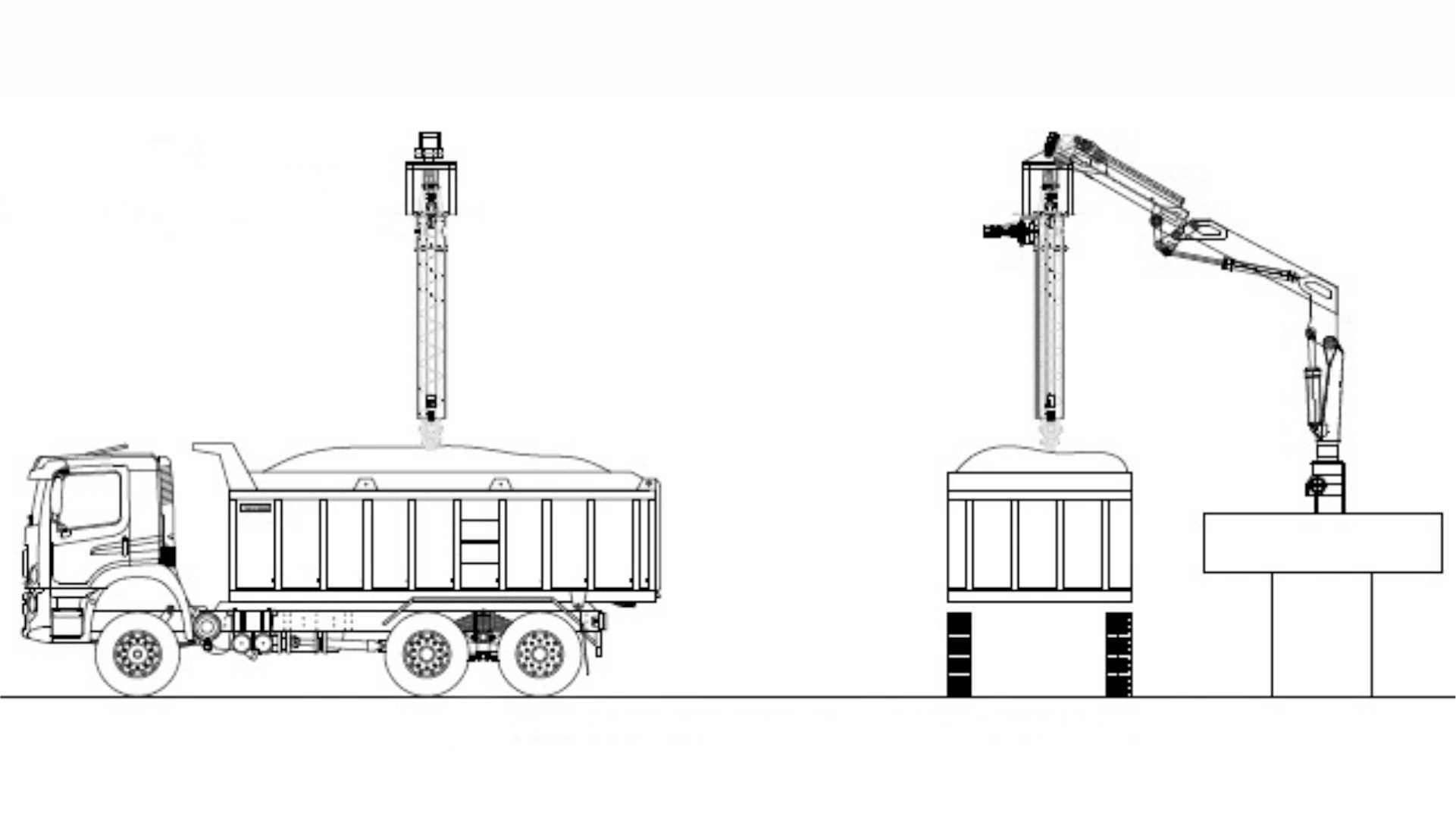

Representative samples are collected by embedding the Auger arm into the material and collect samples from the entire cross section of the trucks / wagons.

The auger is equipped with a bided screw shaft that augers material across the truck / wagon cross section upto a depth of 2 meters.

A crane mounted auger arm rests on a hydraulic jack & can collect increments from the wagon or truck at multiple points, keeping alive the random sampling parameters.

As the sample is drawn it also gets reduces upto 30 mm size due to auger action. On its upward movement the increment is passed through an integrated sample divider that draws representative sample of approx 5 Kg from the collected gross sample and discards the balance material back to the same truck/wagon from where the auger head had collected a representative sample.

The collected increment is simultaneously transferred via a chute to the adjoining sample preparation platform placed on the mobile truck platform.

Insmart’s Auger sample collection system is a heavy-duty machine that has been developed to efficiently extract run-of-mine samples which could include high density contaminants as well.

The truck movement and auger operation process for automated sample collection can be conveniently performed by a trained operator.

The entire sample collection process is powered by diesel genset. The machine and its control room are mounted on a reputed make truck which is powered by a diesel engine of 70 Hp capacity or more.

Sample drawal from entire vertical cross section of the trucks/wagons.

Operation with a variety of materials including cross seam materials.

Advanced hydraulic oil flow control mechanism to assess big boulders/rocks in the auger path.

Functions with a single operator.

| Overall dimensions | 5 x 6 meter |

| Length of cylindrical casing with auger | 2.1 meter |

| Auger Diameter | 300 mm |

| Auger speed | 170 RPM |

| Power Requirement | Upto 70 Hp |

| Control system | Automatic PLC Based controls |