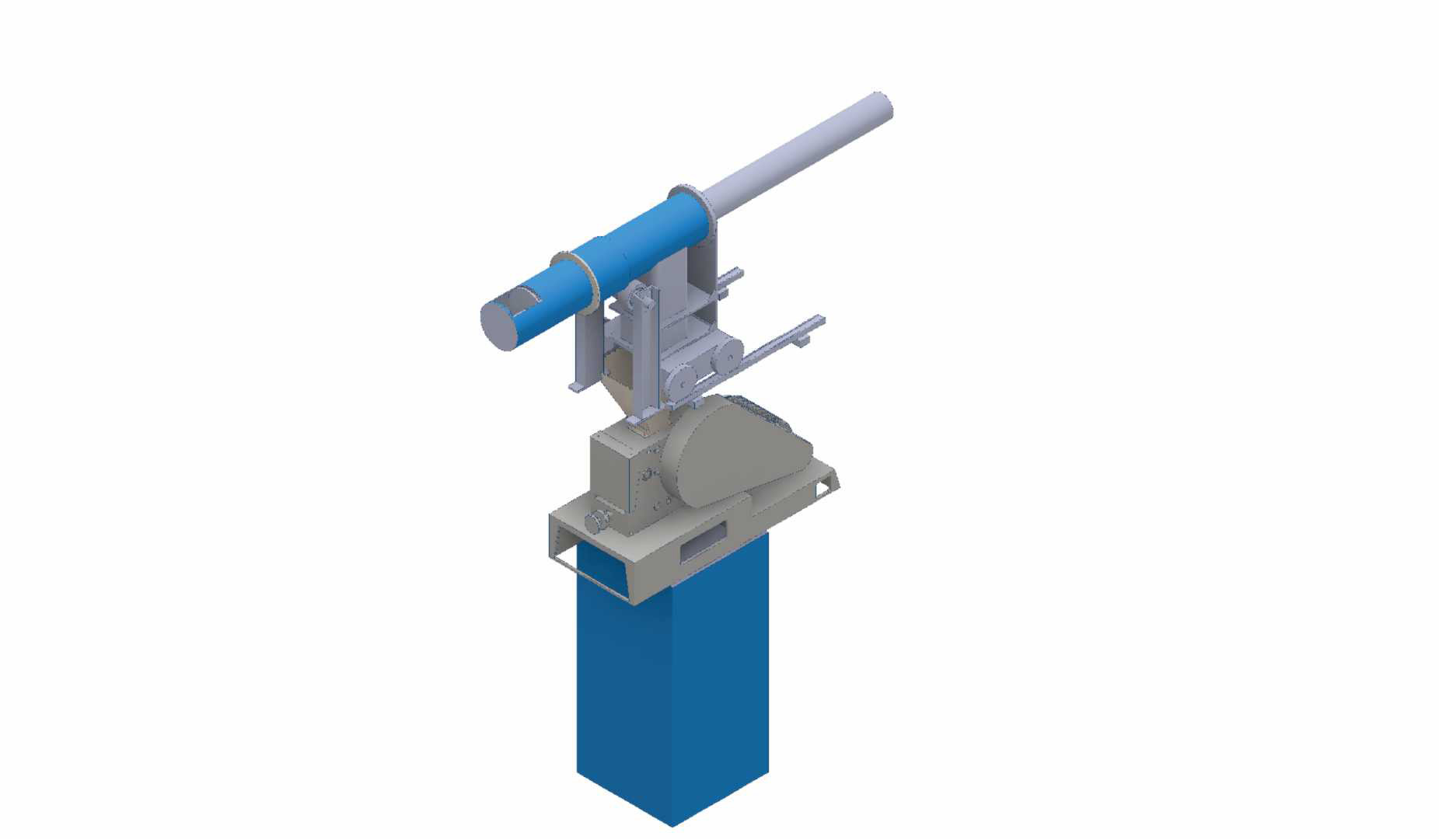

Automatic Clinker Sampler

with integrated Crushers, Dividers and Discard material handling systems

Insmart also provides onsite sample collection and preparation assembly which consists of a crusher, feeder conveyor, sample divider and reject material conveyor.

The sampler is positioned at the grate cooler discharge. In the integrated environment once the sampler arm is retracted from the clinker flow. The sample is emptied into a discharge chute which in turn feeds the clinker crusher.

The integrated crusher accepts entire increment quantity in hot condition and instantaneously crushes it to desired -3 mm size.

A feeder conveyor transfers the material uniformly to the sample divider. Here the material is intercepted and representative material and drawn into a bottle.

The excess material it passed onto a reject material conveyor which feeds the material to the DPC thereby ensuring no material wastage.

The sample bottle is integratable with pneumatic sample transportation system.

Once filled the bottle is capped it is indexed for conveying through pipes.

| Equipment | Integrated crusher | ||||

| Mounting Type | Frame mounting (site condition dependent) | ||||

| Working Principle | Pressure | ||||

| Maximum Feed Size | ≤ 70mm | ||||

| Feed Type | Choke Feeding of upto 5 Kg sample material | ||||

| Output Size | Upto 3 mm | ||||

| Throughput | 20 Kgs/Hr at – 70 mm feed size and – 3 mm output | ||||

| Crushing materials | Clinker upto 5000C | Crushes materials with medium to substantially high hardness and brittleness | |||

| Crushing enclosure [side plates] | Material of construction for side plates – Hardened Steel | ||||

| Motor Drive | Motor Power :

2.2kw |

3

HP Motor |

RPM : 1440 | Volts: 440 | 3 Phase induction Motor |

| Required Power | 3 phase neutral + earthing through 16 amps 4 Pole MCB

[Red, Yellow, Blue, Neutral, earthing] |

||||

| Equipment | Built in sample divider | ||||

| Particle Size | Upto 20 mm | ||||

| Capacity | 20 kg per hour | ||||

| Purpose | To Draw true representative sample in hot condition | ||||

| Main Motor Drive | Special motor drive, with fixed rpm, 230 V, + Neutral & earthing | ||||

| Power | 2 Pole MCB , 4 amps Single Phase | ||||

| Equipment | Integrated reject material conveyor | ||||

| Capability | Discharge excess quantity of hot clinker material back to the DPC. (the conveyor length and orientation is dependent on site location and space availability in the cooler discharge area. | ||||