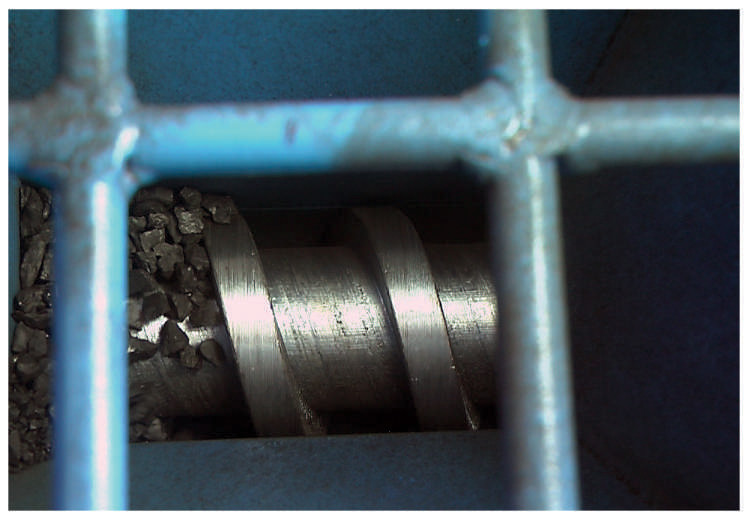

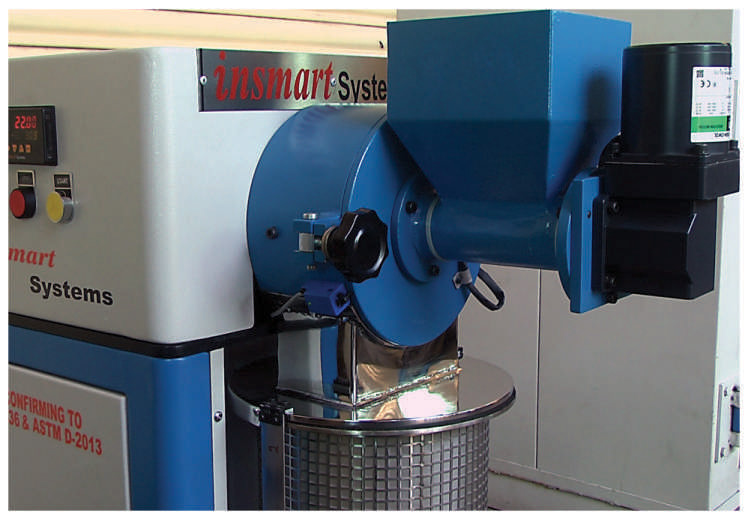

Pulverizes small quantity of Laboratory sample (upto 5 Kg/hour). Sample upto a maximum size of -5 mm can be pulverized to - 212 micron as per the defined particle size distribution in IS 436.