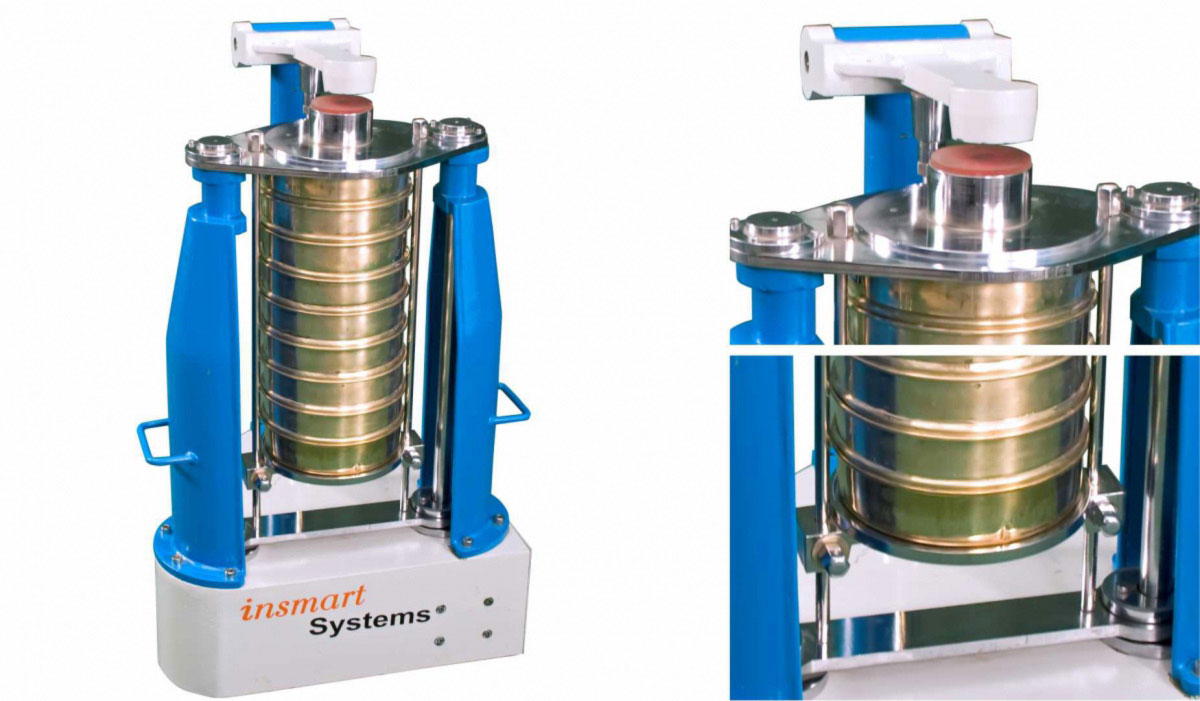

Ro-Tap Sieve Shakers

The Equipment is specifically meant for determining the particle size distribution of sample by dry sieve analysis of various samples in the size range of -10 mm to 38µ.

It is operated on two simultaneous motions an oscillatory motion with tapping given at the top. They provide oscillatory & tapping stroke in the ratio of 280:140 strokes per minute.

| Overall Size of Test Sieves | 200 mm Dia x 50 mm Height. |

| Material of Construction | Brass Frame Fitted with S S Cloth Standard Test Sieves with Brass Frame |

| SS Cloths | 200 mm Dia |

| Purpose / Capacity | For screening geological materials like Rocks, Minerals, Sand, Stem of Sediments and Soil, Iron Ore, Iron Oxide, Ferrite, Brittle Alloys, Graphite etc. |

| Input feed size | - 5mm |

| Material of Construction | Mild Steel |

| Number of Taps | Upto 280 per minute |

| Number of Oscillations | Upto 240 per minute |

| Motor | 0.50 H.P. |

| Power Supply | 415 Volts, 50 Hz A.C. 4 Pole MCB, 10 Amps, 3phase, neutral with earth. |

| Safety Features | Current over load safety for motor protection. |

| Type of mounting | Capable of operating on a level platform / floor mountable. |