Jaw Crusher

Jaw Crusher Machine, Small Jaw Crusher, Portable Jaw Crusher, Jaw Crusher for Sample Preparation

Jaw Crusher is a basic sample preparation unit and is essential to address all primary size reduction requirements. Desired crushing takes place when fed particles experience stress and the compressive pressure exerted by the jaw blade toggling action exceeds its fracture stress. By this action the feed particles are crushed to smaller sizes. The product size will depend upon the crusher blade gap and feed particle characteristics (for eg.: material hardness, weak planes, weathering, thermal history etc.).

Working Principal of Jaw Crusher

Lumpy test material to be crushed is fed into the crushing zone through a hopper. The crushing zone consists of two parallel side walls of hardened and tempered steel and two special profile Jaws. One jaw is provided with oscillatory motion, whereas the other jaw is hinged to adjust the gap and get desired output size through an adjustable screw mechanism. The crushed material comes out from the crushing zone and gets discharged into a large collecting receptacle. Provision is made to extract the flying dust, through vacuum suction system.

Highlights of Crushing Environment:

150 mm Jaw opening accepts input size suitable for a variety of lump sizes.

High material reduction, upto 3 mm size, is achieved by faster and more efficient crushing with 2 stage process.

Movable Jaw with toggle speed of numerous strokes per minute.

Jaw blades made from hardened steel provide improved analytical results as they give minimum sample contamination.

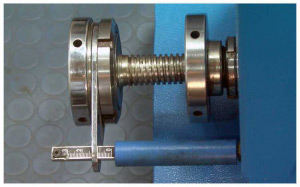

Gap Adjustment Feature:

A jaw blade gap adjustment system provides a continuous gap width setting arrangement to produce desired size reduction.

Gap width setting range:

0 to 50 mm in increments of 1 mm

Safety Features:

To help machine operator's material handling activities, the Jaw crusher is provided with an Over load relay which efficiently trips the motor in cases of material clogging due to sudden material dumping.

Pulley guard prevents all accidental contacts with the belt and pulley assembly while machine is in operation.

- Ideal for Primary & secondary crushing of the ores/minerals like: Magnetite, Hematite, Laterite, Limestone, Bauxite, Manganese ore, Quartz, Chromite, Coal, Pet coke, Met coke and Ferro Alloys.

- Firm design does not require any foundations and gives customer a freedom to shift the equipment as per the requirement.

- Dynamic Jaw Blade set gap adjustment mechanism makes it convenient to crush the material to different sizes by performing simple jaw blade gap adjustments.

- Eliminates the need for procuring multiple crushers.

- Available in 3 variants.

- Environment Friendly equipment: Comes with provision of dust extraction systems in-order to arrest the flying dust that gets generated during sample disintegration process.

- High speed operation, economical mode, robust & space saving designs make Insmart crusher a favourable choice for instant size reduction of diverse material samples with repeatedly accurate performance.

- A range of Jaw crushers are available to crush the materials with top size ranging from 150 mm to 65 mm and provide final outputs of upto 3mm.

- All Insmart Jaw crushers achieve extremely rapid comminution by toggling action.

- Extraordinarily fast and effortless maintenance.

- Extremely forces generated can bring about fragmentation of very hard materials.

| Mounting Type | Floor mounting | No foundation required | ||||||||

| Working-Principle | Pressure | |||||||||

| Maximum Feed Size | IJC 3 | ≤ 150mm | IJC 2 | ≤ 100mm | IJC 1 | ≤ 65 mm | ||||

| Lumps bigger than designated feed size can be manually broken before feeding them on to the hopper | ||||||||||

| Feed Hopper | Batch Feeding Hopper | To ensure non-choking batch feeding into the crushing media | ||||||||

| Throughputs *All crushers with unique jaw blade gap adjustment mechanism to get different desired outputs | IJC -3: ~1000 Kgs/Hr at -150 mm feed and 50mm output at a sample moisture of 5-6% | |||||||||

| IJC -1: 100 Kgs/Hr at -65 mm feed and 12.5mm output at a sample moisture of 5-6% | ||||||||||

| IJC -2: 350 Kgs/Hr at -100 mm feed and 12.5mm output at a sample moisture of 5-6% | ||||||||||

| Crushing materials | Ideal for Primary & secondary crushing of the ores/minerals like: Magnetite, hematite, Laterite, Limestone, Bauxite, Manganese ore, Quartz, Chromite, Coal, Pet coke, met coke and Ferro Alloys Crushes materials with medium to substantially high hardness and brittleness | |||||||||

| Hardened steel Jaw Blades | IJC 3 Size: 325 x 151mm x 30mm | IJC 2 Size 270 x 100 x 28mm | IJC 1 Size : 260 x 100 x 19mm | |||||||

| Material of construction for movable and fixed Jaws [Anti material slip, abrasion resistant] Like: Hardened Steel, Manganese Steel, Tungsten Carbide coated, Tungsten carbide lined | ||||||||||

| Crushing enclosure side plates | Material of construction for side plates | Hardened Steel | ||||||||

| Motor Drive IJC 3 | Motor Power : 3.7 kw / 5.5kw | 5HP/7.5HP Motor | RPM : 1440 | Volts: 440 | 3 Phase induction Motor | |||||

| Motor Drive IJC 2 | Motor Power : 2.2/3.7kw | 3/5HP Motor | RPM : 1440 | Volts: 440 | ||||||

| Motor Drive IJC 1 | Motor Power : 1.5 kw | 2 HP Motor | RPM : 1440 | Volts: 440 | ||||||

| Required Power [to be provided by end user ] | 3 phase neutral + earthing through 16 amps 4 Pole MCB (Red, Yellow, Blue, Neutral, Earthing) | |||||||||

| Total Machine weight [with packed material] | IJC 3 | 770 Kgs | Machine weight : 650 kgs | Wooden box weight: 120 Kgs | ||||||

| IJC 2 | 620 Kgs | Machine weight : 500 kgs | Wooden box weight: 120 Kgs | |||||||

| IJC 1 | 470 Kgs | Machine weight : 350 kgs | Wooden box weight: 120 Kgs | |||||||

| Machine Size [in millimeters] | IJC.3 | Length: 1220 | Width: 599 | Height : 1020 | ||||||

| IJC.2 | Length: 1120 | Width: 450 | Height : 840 | |||||||

| IJC.1 | Length: 980 | Width: 500 | Height : 800 | |||||||

| Dust Extraction Systems [optional] | Removes airborne dust, improves operating environment and eliminates cross contamination | |||||||||

| Purpose | sample crushing for laboratory use | |||||||||