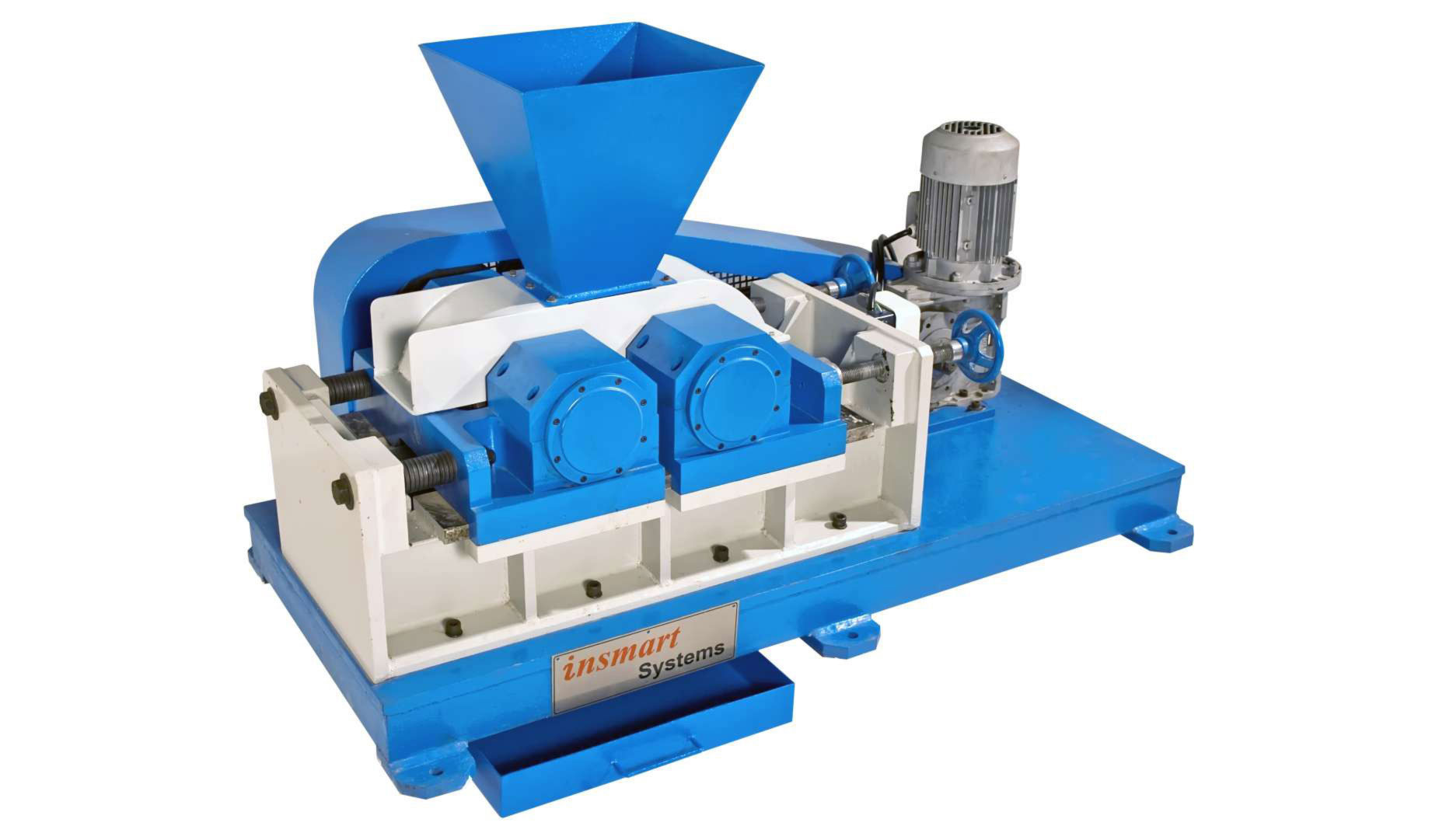

Roll Crusher

Insmart Roll Crusher

For fast and effective reduction of feed material by crushing between the rolls.

Principal of operation:

The hard and brittle geological materials are trapped between the two rotating grooved rolls. One of the roll is given power through a “V” belt pulley system and is fixed on a stationary bearing block. The gap between the roll can be adjusted by a spring loaded screw rod. After the desired gap is adjusted the position is locked by a lock nut.

High pressure Roll Crushers having constant preset load with high pressure hydraulic accumulator are also manufactured.

Provision is made to change the speed of roll electronically.

- Ideal for secondary crushing of the ores/minerals like: Magnetite, Hematite, Laterite, Limestone, Bauxite, Manganese Ore, Quartz, Chromite, etc.

- The crushing is due to entrapment of particles between the rolls thereby the particle gets ruptured this also facilitates low energy consumption during grinding.

- Unique design that operates two rolls with single drive.

- Insmart Roll Crushers have got a unique facility of gap adjustment by two screw mechanism that can easily change the nip angle for getting the desired reduction ratio.

- Firm design does not require any foundations and gives customer a freedom to shift the equipment as per the requirement.

- A range of roll crushers are available to crush with a feed size range of -20 to -3 mm size.

| Roll Crusher with grooved & plain rolls | Roll Crusher with grooved & plain rolls of 200mm diameter and 150mm width |

| Roll Diameter | 250 mm (Grooved / Plain) |

| Rolls width | 150 mm |

| Type of Rollers | Manganese Steel/Hardened Steel |

| Feed Size | Upto -25 mm |

| Output Size | Upto -1 mm |

| Crushing Capacity | ~200 Kgs/Hr (depending on reduction ratio, it varies) |

| Roller Speed | 120 rpm |

| Hopper Feeder | Feed Hopper with size 350 X 350mm provided with screen of 20mm dia openings for protecting the operator hands and oversize particles from entering the crushing zone |

| Roll Gap Adjustment | The gap between the roll can be adjusted by a spring loaded screw rod from 1-12 mm |

| V- Belts | One of the roll is given power through a V-Belt pulley system and is fixed on a stationary bearing block |

| Motor Size | 2.25 KW (3 HP) Heavy Duty Motor |

| Power Supply | 3 Phase, 440 V, 50 Hz, AC Supply with neutral earthing |

| Type of mounting | Mounted on fabricated steel frame |