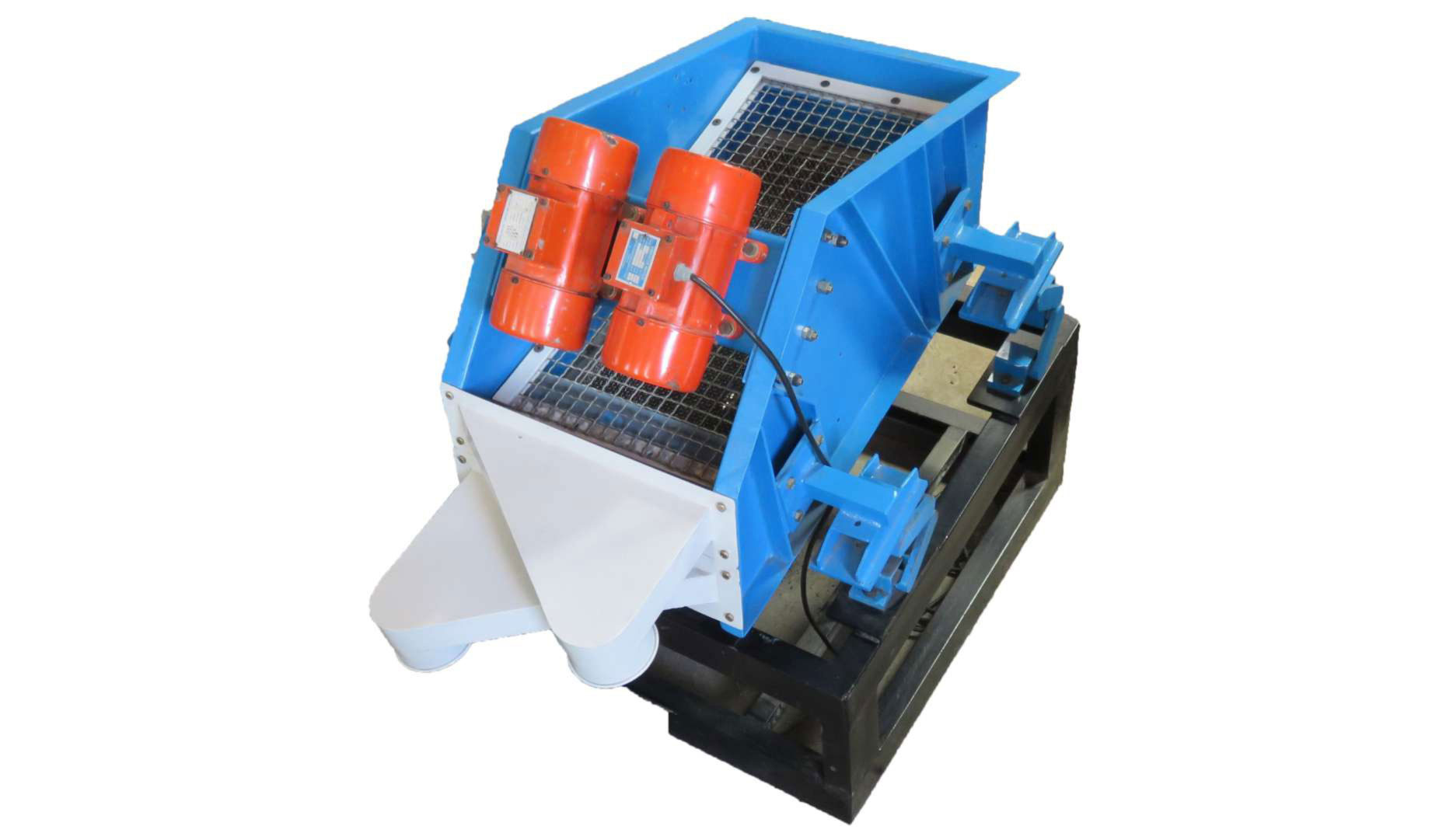

Single, Double & Multi Deck Vibratory Screens

Insmart Vibratory Screens

Classifying lumpy samples is best achieved by using Insmart decked vibrating screens which comes in three variants of single, double & multi deck vibrating screens.

The inclined screen design is proven in Limestone, Bauxite, Laterite and mining ore applications.

Side tensioned wire mesh cloth screen decks are made of high strength materials.

Multiple size decks on a single platform are available.

High-performance vibro-motors bring about vigorous and continuous shaking of size fraction.

- Linear Straight line Action for a smooth Particle movement

- Excellent Separation

- Screen Decks are easily Changeable

- Zero Maintenance

- Motor mounting on suspended frame for better vibration transfer

- Mounted Twin Motor Drives

Structured Body:

Body of a Vibrating Screen consists of a base frame and screen supporting structure. The base frame is welded using heavy channels and angles in order to contain the continuous vibration. Screen supporting structure and screen are made from wear resistant steel.

High strength Springs:

Suitable helical coiled springs are provided with the Vibrating Screen. Entire screen holding structure is supported by these springs. Special care has been taken to manufacture these springs which bear entire load along with continuous vibratory motion.

Driving Motor:

The foundation frame of the Driving Motor is provided by projection on one side of the Vibrating Screen and supports from base frame are also provided to hold the motor foundation. The size of motor varies as per the size of Vibrating Screen. Power requirement is 3 phase earthing through 16 Amps, 3 phase MCB.

Coiled Screen:

The screens are made from special coiled sheets to provide sufficient resistance to wear and tear. The mesh size of the screening surface can be made as per the requirements of the customer.

The number of screening surface depends upon the number of decks of the screen. The inclination is given to the screen according to the suitability of work.

Customer is advised to check on various factors while selecting screening equipment such as:

- Particle shape and size

- Feed rate, required number of size distribution

- Moisture content

- Bulk density of material

- Number of products to be screened

- Method of loading

For each application there is an optimum combination of amplitude, frequency and attack angle.

The major benefits of horizontal screens include lower overall height and more-efficient fine processing.

The efficiency improvements are mainly due to a lower travel rate of the material.