Tabletop Jaw Crusher

Jaw Crusher Machine, Small Jaw Crusher, Portable Jaw Crusher, Jaw Crusher for Sample Preparation

Insmart Table Top Jaw Crusher is specially designed for sample preparation in the laboratory. The compact Jaw Crusher and be mounted on any laboratory bench or table. Table Top jaw crusher is vibration and dust free crusher supporting the lab environment

Working Principal of Jaw Crusher

Lumpy test material to be crushed is fed into the crushing zone through a hopper. The crushing zone consists of two parallel side walls of hardened and tempered steel and two special profile Jaws. One jaw is provided with oscillatory motion, whereas the other jaw is hinged to adjust the gap and get desired output size through an adjustable screw mechanism. The crushed material comes out from the crushing zone and gets discharged into a large collecting receptacle.

Provision is made to extract the flying dust, through vacuum suction system.

Suitable for crushing brittle metal/alloys, ceramic, composites & glasses, geological materials like Rocks, Minerals, Iron Ore.

Robust and easy design to maintain for longer life.

Digital display of process parameters.

Suitable for crushing brittle metal/alloys, ceramic, composites & glasses, geological materials like Rocks, Minerals, Iron Ore.

Robust and easy design to maintain for longer life.

Digital display of process parameters.

MOC of jaw and side plate: Zirconium oxide, Tungsten Carbide lined, Tungsten Carbide Coated, Stainless Steel & Hardened Steel.

Feed material input size less than 40 mm.

Final size after crushing upto 0.5 mm

Variable speed selection of moving jaw.

- Jaw crusher is fitted with feeding chute assuring no blockage of feed line, no splash back of feed, minimization of exit of fines and ease of cleaning.

- Digital display of bottom gap with a minimum resolution of 0.1 mm. Bottom gap of crushing jaw adjustable between 0 to 11 mm in steps not more than 0.1 mm. Easy to adjust the bottom gap viz rotating a smooth knob.

- Bottom gap adjustment mechanism has suitable safety feature to avoid inadvertent damage of jaws.

- Provision for reversing the direction of rotation to remove inadvertent blockage of jaws (in case of over feeding).

- Memory for previous programme (e.g., setting parameters).

- Receiver tray with suitable lid for avoiding cross contamination from earlier crushing.

Collector Tray capacity ~3 litres. - Safety features i.e., emergency stop buttons, all movable components are suitably guarded etc.

- Jaw crusher has dust free crushing with dust extraction system

- Operating noise emission level of crusher is less than 90 dB in standard operation conditions.

- Power connection: Single phase, 230 V, 50 Hz

- Drive shaft mechanism with 3 phase 1.5 HP motor having frequency convert.

- High speed operation, economical mode, robust & space saving designs make Insmart crusher a favourable choice for instant size reduction of diverse material samples with repeatedly accurate performance.

- A range of Jaw crushers are available to crush the materials with top size ranging from 150 mm to 65 mm and provide final outputs of upto 3mm.

- All Insmart Jaw crushers achieve extremely rapid comminution by toggling action.

- Extraordinarily fast and effortless maintenance.

- Extremely forces generated can bring about fragmentation of very hard materials.

| Technical Specifications: Insmart Jaw Crusher (Table Top Model) | ||||||

| Mounting Type | Benchtop/ Floor mounting | No foundation required | ||||

| Working Principle | Impact | |||||

| Maximum Feed Size | ≤ 40 mm | |||||

| Final Fineness | ≤ 0.5 mm | |||||

| Lumps bigger than designated feed size can be manually broken before feeding them on to the hopper | ||||||

| Feed Hopper | Batch Feeding Hopper | To ensure non-choking batch feeding into the crushing media | ||||

| Throughputs *All crushers with unique jaw blade gap adjustment mechanism to get different desired outputs | 60 Kgs/Hr at -40 mm feed and 5 mm output at a sample moisture of 5-6% | |||||

| Gap Width Display | Digital | |||||

| Gap With Setting | 0-11 mm in increment of 0.1 mm | |||||

| Collector Capacity | 3 Liter | |||||

| Crushing materials | Ideal for Primary & secondary crushing of the ores/minerals like:

Magnetite, Hematite, Laterite, Limestone, Bauxite, Manganese ore, Quartz, Clinker, Chromite, Coal, Pet coke, Met coke and Ferro Alloys, Crushes materials with medium to substantially high hardness and brittleness |

|||||

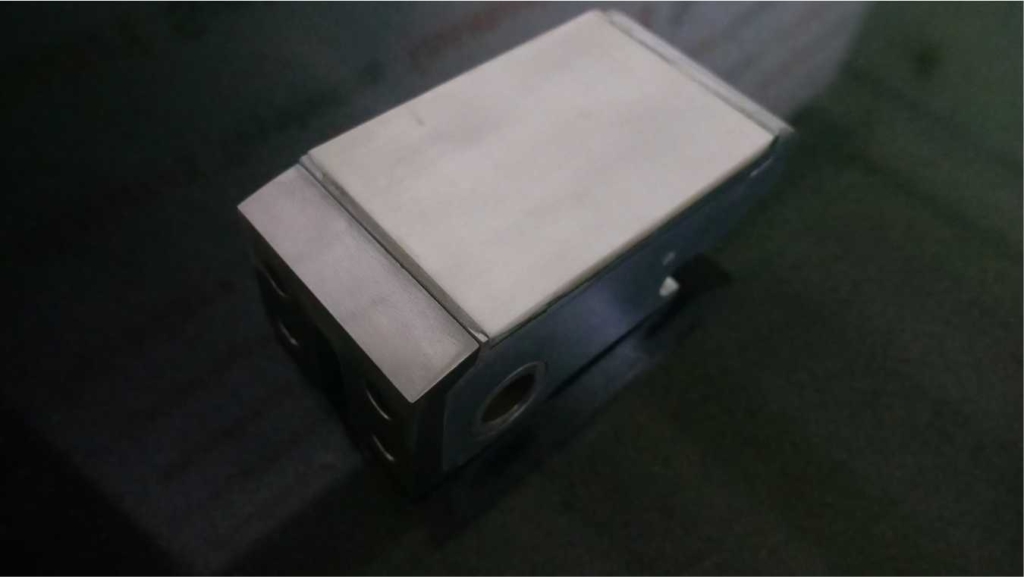

| Jaw Blade Size | Size: 45 x 59 x 12 mm | |||||

| Jaw Blade MOC | Removable Jaw Blade set available in Hardened Steel, Stainless Seel, Tungsten Carbide, Zirconia | |||||

| Floor area (m²) | 0.235 | |||||

| Material of construction for movable and fixed Jaws [Anti material slip, abrasion resistant materials]

Like: Hardened Steel, Manganese Steel, Stainless Steel, Tungsten Carbide coated, Tungsten carbide lined, Zirconium Oxide |

||||||

| Crushing enclosure side plates |

Material of construction: Hardened Steel/ Stainless Steel/ Zirconia | |||||

| Motor Drive | Motor Power: 1.1 kw | 1.5 HP Motor | RPM :1440 | Volts: 440 | 3 Phase induction Motor | |

| Required Power [to be provided by end user] | Single phase neutral + earthing through 20 amps 3 Pole MCB (Red, Neutral, Earthing) |

|||||

| Overload Relay | 5 Amps | |||||

| IP Protection Code | IP 20/ IP 00 at ventilation slot | |||||

| Total Machine weight [with packed material] | 180 Kgs | Machine weight: 80 kgs | Wooden box weight: 100 Kgs | |||

| Machine Size [in millimetres] | Length: 520 | Width: 420 | Height: 460 | |||

| Dust Extraction Systems [optional] | Removes airborne dust, improves operating environment and eliminates cross contamination | |||||

| Purpose | Sample crushing for laboratory use | |||||